Why Ammonium Fluorosilicate Is the Perfect Chemical Polishing Agent

In modern industrial processes, achieving ultra-smooth surfaces with precision is critical for many advanced applications. From optical lenses to semiconductor wafers, the demand for flawless finishes has driven the development of innovative polishing agents. Among these, ammonium fluorosilicate (NH4)2SiF6 stands out as a highly effective and versatile chemical polishing agent. This article explores the reasons for its widespread use and the mechanisms behind its success in delivering superior surface quality.

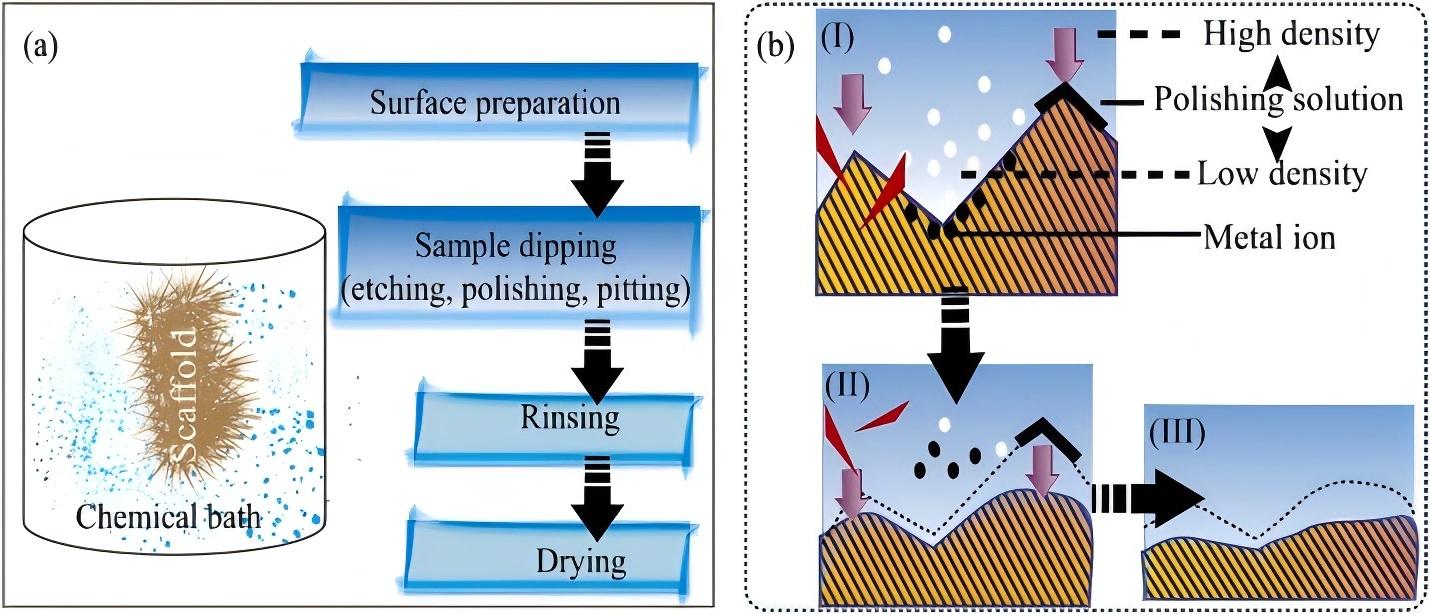

Understanding Chemical Polishing

Chemical polishing is a process that uses reactive substances to selectively remove surface material at the microscopic level. Unlike mechanical polishing, which relies on physical abrasion, chemical polishing achieves a smoother finish by dissolving surface irregularities chemically. This method minimizes damage and ensures consistent results across a variety of materials.

Ammonium fluorosilicate plays a pivotal role in this domain due to its unique chemical properties, particularly its ability to interact with siliceous and metallic surfaces. Its efficiency as a chemical polishing agent is rooted in its reactivity with surface oxides, controlled etching properties, and ability to enhance surface uniformity without introducing subsurface stress.

Key Properties of Ammonium Fluorosilicate

1、Reactivity with Silica and Oxides

Ammonium fluorosilicate contains fluoride ions, which exhibit a high affinity for silicon and metal oxides. This makes it ideal for surfaces containing silica or oxide layers, as it can selectively remove these compounds.

2、Controlled Solubility

The compound dissolves readily in water, allowing for the precise adjustment of its concentration in polishing solutions. This tunability ensures controlled reactions, reducing the risk of over-etching or uneven polishing.

3、Non-Abrasive Nature

Unlike mechanical polishing agents, ammonium fluorosilicate does not rely on abrasion. This eliminates the risk of scratching or introducing microcracks, making it particularly suitable for delicate or high-precision materials.

Why Is Ammonium Fluorosilicate Preferred?

1、Enhanced Surface Smoothness

Ammonium fluorosilicate excels in creating ultra-smooth surfaces by selectively removing microscopic irregularities. This is particularly important for applications where surface imperfections can compromise performance, such as in optical lenses or semiconductor wafers.

2、Uniform Material Removal

The compound’s ability to etch surfaces evenly ensures that material is removed uniformly across the entire substrate. This uniformity is essential for achieving a consistent finish, especially in industrial applications requiring tight tolerances.

3、Compatibility with Diverse Materials

While it is most effective on siliceous materials, ammonium fluorosilicate also performs well on metals with oxide layers, making it a versatile choice for a variety of industries.

4、Eco-Friendly Alternatives

Compared to traditional polishing methods that rely on abrasive particles, chemical polishing with ammonium fluorosilicate generates fewer particulates and less waste, contributing to a cleaner and more sustainable manufacturing process.

Applications Across Industries

Ammonium fluorosilicate’s versatility is evident in its diverse industrial applications:

1、Optical Manufacturing

In the production of lenses, mirrors, and prisms, even minute imperfections can distort light and degrade performance. Ammonium fluorosilicate ensures a flawless finish by dissolving surface irregularities, enhancing the optical clarity and performance of these components.

2、Semiconductor Fabrication

Silicon wafers form the backbone of modern electronics. Before being processed, these wafers require a pristine surface free of contaminants and irregularities. Ammonium fluorosilicate selectively etches the silicon surface, removing oxides and impurities without introducing stress or defects, thereby enabling the production of reliable semiconductor devices.

3、Metal Surface Preparation

For metals such as aluminum, titanium, and stainless steel, surface quality is critical for applications ranging from aerospace to medical devices. Ammonium fluorosilicate removes surface oxides effectively, preparing the material for subsequent treatments like anodizing or coating.

4、Artistic and Functional Glass Etching

The compound’s ability to dissolve silica makes it invaluable for glass etching, where intricate patterns or smooth finishes are required. From decorative glassware to architectural elements, ammonium fluorosilicate facilitates precision and artistry.

How Ammonium Fluorosilicate Works: The Chemistry

The effectiveness of ammonium fluorosilicate as a polishing agent lies in its reaction mechanisms:

1、Interaction with Silica:

When applied to siliceous surfaces, ammonium fluorosilicate reacts with silica to form soluble hexafluorosilicic acid. This reaction selectively dissolves high points on the surface, reducing irregularities without affecting the bulk material.

2、Removal of Metal Oxides:

For metallic substrates, the fluoride ions in ammonium fluorosilicate react with surface oxides, forming soluble metal fluorides. This process not only cleans the surface but also improves adhesion for coatings or other treatments.

3、Self-Limiting Action:

The reactions slow as the target material becomes smoother, preventing over-polishing and ensuring a controlled finish.

Innovations and Future Prospects

As industries demand ever-higher surface quality, ammonium fluorosilicate continues to evolve as a critical tool. Emerging technologies, such as nanofabrication and precision optics, are expanding its use, while researchers explore new formulations to enhance its efficiency and environmental friendliness.

Additionally, advancements in automation are integrating chemical polishing processes into streamlined production lines, further increasing the efficiency and scalability of ammonium fluorosilicate-based polishing.

Ammonium fluorosilicate has cemented its place as a cornerstone of chemical polishing technology. Its unique ability to deliver smooth, uniform finishes without the drawbacks of mechanical abrasion makes it indispensable in industries ranging from optics to semiconductors.

As technology advances, the compound’s role will only grow, shaping the future of precision manufacturing. By continuing to refine its applications and addressing environmental considerations, ammonium fluorosilicate ensures a balance between industrial progress and sustainability.