Ammonium Tetrafluoroborate Boosting Resin Coatings

Resin coatings, materials applied to various surfaces, are primarily composed of resin, solvents, additives, and pigments. With the continuous advancement of technology, resin coatings, as sophisticated coating materials, have undergone constant research and innovation. Their applications have expanded beyond traditional sectors such as construction and automotive industries to high-tech fields like electronics, aerospace, and energy, providing diverse solutions across various industries. Ammonium tetrafluoroborate, a common inorganic flame retardant, significantly enhances the flame resistance of resin coatings when incorporated.

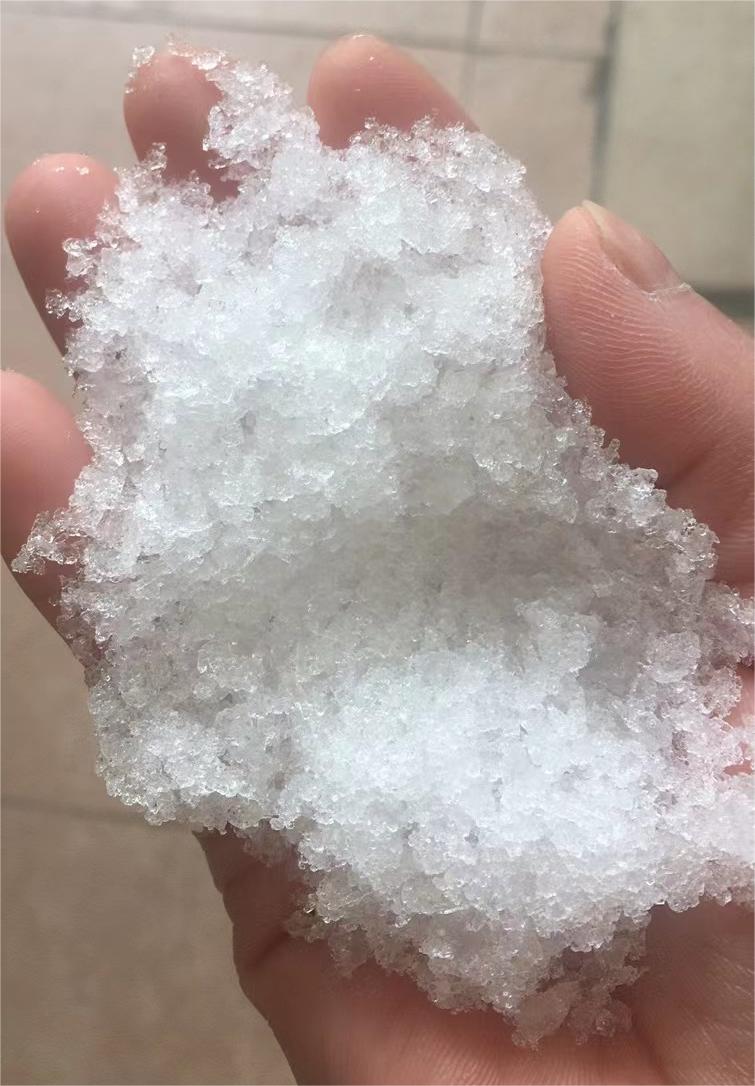

Ammonium tetrafluoroborate (chemical formula NH4BF4) consists of ammonia and tetrafluoroborate ions, presenting itself as a white crystalline solid with good solubility in water and some organic solvents. Being an inorganic salt without organic carbon structures, it exhibits resistance to combustion at high temperatures. Additionally, under elevated temperatures, ammonium tetrafluoroborate decomposes, releasing fluorine elements that effectively inhibit the spread of flames. By absorbing and decomposing heat, it reduces the heat released during material heating, further slowing down the spread of flames.

Catalytic Principles of Ammonium Tetrafluoroborate in Resin Coatings

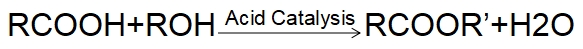

Ammonium tetrafluoroborate, as a strong acid, utilizes its hydrogen ions (H⁺) as acid catalysts, promoting esterification and aldol condensation reactions in the coatings.

In esterification reactions, acid catalysts accelerate the reaction between alcohols and carboxylic acids, forming ester structures. This reaction aids in improving the chemical resistance and hardness of the coatings.

For aldol condensation reactions involving aldehydes and alcohols, strong acid catalysts similarly expedite the reaction, contributing to the cross-linking and curing of coatings.

![NH4[BF4] NH4[BF4]](https://img.waimaoniu.net/1473/1473-202401061104455381.png)

Esterification and aldol condensation reactions are common cross-linking reactions in coatings. By accelerating these reactions, ammonium tetrafluoroborate contributes to increasing the degree of cross-linking in coatings, enhancing hardness and wear resistance. The elevated degree of cross-linking also improves the chemical resistance of coatings, making them more resistant to erosion and corrosion by chemical substances.

Applications of Ammonium Tetrafluoroborate as an Additive in Resin Coatings

1、Coatings and Coating Industry: Ammonium tetrafluoroborate is commonly used as a catalyst and additive in resin coatings to improve hardness, wear resistance, and chemical resistance. This additive enhances coating performance, making it suitable for various environmental conditions.

2、Fire Retardant Coatings: Due to the flame-retardant properties of the fluorine element in ammonium tetrafluoroborate, it finds extensive use in fire retardant coatings. It contributes to improving the flame retardancy of coatings, reducing the risk of material combustion, and is suitable for applications requiring enhanced flame resistance.

3、Metal Coatings: In the field of metal coatings, ammonium tetrafluoroborate serves as a catalyst, promoting the curing and cross-linking of resin coatings on metal surfaces, enhancing their corrosion resistance and wear resistance.

4、Electronics and Electrical Equipment: Resin coatings are widely used in electronics and electrical equipment, and the addition of ammonium tetrafluoroborate improves coating performance, making it suitable for protecting and insulating electronic components.

5、Building and Decorative Coatings: In building and decorative coatings, ammonium tetrafluoroborate can improve the durability and stain resistance of coatings, making them more resilient to indoor and outdoor environmental challenges.

6、Automotive Coatings: In automotive manufacturing, resin coatings are commonly used for the protection and aesthetics of automobile surfaces. The addition of ammonium tetrafluoroborate enhances the performance of coatings, increasing their scratch resistance and weather resistance.

7、Aerospace Industry: In the aerospace sector, coatings are required to have high strength, lightweight, and high-temperature resistance. The use of ammonium tetrafluoroborate contributes to improving the performance of resin coatings.

In conclusion, ammonium tetrafluoroborate exhibits various advantages in its application in resin coatings. As an inorganic flame retardant, it significantly enhances the fire resistance of resin coatings, slowing down the spread of flames. Additionally, as a strong acid catalyst, ammonium tetrafluoroborate promotes esterification and aldol condensation reactions, further increasing the hardness, wear resistance, and chemical resistance of coatings. Its crucial role in coating formulations makes it an indispensable component widely used in coating and coating industries, including fire retardant coatings, metal coatings, electronic devices, architectural decoration, automotive coatings, and aerospace applications. The characteristic of releasing fluorine elements during decomposition at high temperatures provides additional flame-retardant effects, making it an essential part of multi-domain coating technologies.