How Sodium Fluoroborate (NaBF₄) is Revolutionizing Household Appliances and Industrial Electroforming

Sodium Fluoroborate (NaBF4) is a versatile compound that finds its application in various industries, ranging from household appliances to the production of electroformed shells in industrial settings. This article will delve into the specifics of how NaBF4 is utilized in these areas, with a particular focus on the chemical principles involved. By understanding the underlying mechanisms, we can better appreciate the importance of this compound in both everyday and industrial contexts.

Sodium Fluoroborate in Household Appliances

Sodium Fluoroborate is widely used as a fluxing agent in the manufacturing of household appliances. In this context, its primary role is to assist in the soldering process, which is crucial for joining metal parts together in a durable and efficient manner.

1. The Soldering Process: Soldering involves melting a filler metal (solder) that has a lower melting point than the workpieces to be joined. NaBF4 acts as a flux, which is essential in this process for several reasons:

● Oxide Removal: Metals naturally form an oxide layer when exposed to air, which can prevent the solder from properly bonding with the metal surface. NaBF4 helps remove this oxide layer by reacting with the metal oxides to form a molten layer of borates, which is then easily displaced by the solder.

● Surface Wetting: By promoting the wetting of the metal surfaces, NaBF4 ensures that the solder spreads evenly, creating a strong and reliable joint. This is particularly important in appliances where electrical and thermal conductivity are critical.

● Corrosion Prevention: NaBF4 also helps prevent oxidation during the soldering process, thereby reducing the risk of corrosion, which could compromise the longevity of the appliance.

2、Applications in Specific Appliances: NaBF4 is used in various household appliances, including refrigerators, washing machines, and air conditioning units. In these devices, numerous metal components need to be joined together, and the reliability of these joints is paramount for the appliance's functionality and safety.

Sodium Fluoroborate in Industrial Electroformed Shell Production

In the industrial sector, Sodium Fluoroborate plays a crucial role in the production of electroformed shells. Electroforming is a process where metal is deposited onto a mold through electroplating, and NaBF4 is used to enhance the quality and precision of the final product.

A、The Electroforming Process: Electroforming involves the deposition of metal onto a pre-shaped mold by passing an electric current through a solution containing metal ions. This process is highly controlled to produce shells with intricate details and exacting tolerances.

B、Role of Sodium Fluoroborate: NaBF4 is added to the electroforming bath as a complexing agent. It binds with metal ions in the solution, stabilizing them and allowing for a more uniform deposition of the metal onto the mold. The specific roles of NaBF4 in electroforming include:

● Improved Surface Finish: By stabilizing metal ions, NaBF4 helps achieve a smoother and more consistent surface finish on the electroformed shell. This is essential for applications requiring high precision, such as in aerospace or medical devices.

● Control of Deposition Rate: NaBF4 assists in regulating the rate of metal deposition, ensuring that the shell is formed with the desired thickness and uniformity. This control is crucial in preventing defects such as warping or uneven thickness, which could compromise the structural integrity of the shell.

● Enhanced Adhesion: The presence of NaBF4 in the bath enhances the adhesion of the deposited metal to the mold, resulting in a stronger and more durable shell.

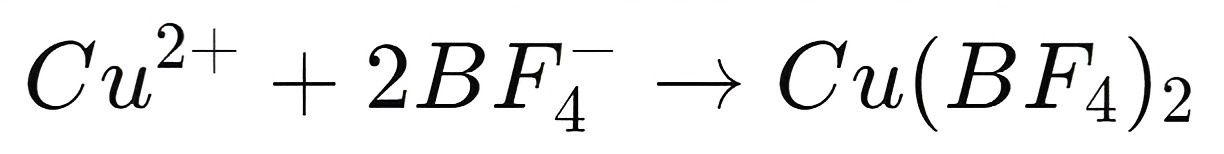

C、Chemical Reactions Involved: During electroforming, NaBF4 undergoes several reactions that facilitate the process. For instance, in a copper electroforming bath, NaBF4 helps to form copper fluoroborate complexes, which are more stable and allow for controlled release of copper ions onto the mold. The overall reaction can be represented as:

This complex is then reduced at the cathode, depositing pure copper onto the mold, while the fluoroborate ions remain in the solution, ready to participate in further complexing reactions.

Advantages of Using Sodium Fluoroborate

The use of NaBF4 in both household appliances and electroforming offers several advantages:

● Precision and Quality: NaBF4 allows for high precision in metal joining and electroforming, ensuring that the final products meet stringent quality standards.

● Cost-Effectiveness: The stability and efficiency provided by NaBF4 reduce the need for expensive rework or material wastage, making the production process more cost-effective.

● Versatility: NaBF4 can be used with various metals, including copper, nickel, and silver, making it suitable for a wide range of applications.

Sodium Fluoroborate is a critical component in the manufacturing of household appliances and the production of electroformed shells. Its ability to enhance soldering and electroforming processes makes it invaluable in both industries. By understanding the chemical principles behind its use, manufacturers can continue to produce high-quality, reliable products that meet the demands of modern consumers.

This detailed exploration of NaBF4's applications highlights its importance in both everyday and industrial contexts, ensuring that its benefits are fully leveraged while maintaining safety and environmental standards.