The Application of Potassium Fluoride in the Manufacturing of Specialty Glass

Potassium fluoride (KF) plays a significant role in the manufacturing of specialty glass due to its unique chemical and physical properties. Specialty glass, used in high-performance applications such as optics, electronics, and protective materials, requires precise control over its composition and characteristics. The inclusion of potassium fluoride in the glass formulation enhances these properties, making it an indispensable component in the specialty glass industry. This article explores the reasons behind the use of potassium fluoride in specialty glass manufacturing and outlines the advantages it provides.

Chemical and Physical Properties of Potassium Fluoride

Potassium fluoride is an inorganic compound with the formula KF. It is highly soluble in water and exhibits strong ionic bonds, which contribute to its high melting point and stability. These properties make it an effective flux in the glass-making process, where it serves to lower the melting temperature of silica and other glass-forming oxides.

Reasons for Using Potassium Fluoride in Specialty Glass

1、Lowering the Melting Point:

One of the primary reasons for adding potassium fluoride to glass formulations is its ability to lower the melting point of the mixture. This reduction in melting temperature is crucial for energy conservation and efficiency in the glass manufacturing process. Lowering the melting point allows for the glass to be processed at lower temperatures, reducing energy consumption and wear on equipment.

2、Improving Optical Properties:

Potassium fluoride can significantly enhance the optical properties of glass. By modifying the refractive index and dispersion properties, KF helps in producing glass with specific optical characteristics. This is particularly important in the production of optical lenses, prisms, and other precision instruments where clarity and light transmission are paramount.

3、Enhancing Chemical Stability:

Glasses containing potassium fluoride exhibit improved chemical stability, making them more resistant to acids and bases. This property is advantageous in applications where the glass is exposed to harsh chemical environments, such as laboratory equipment and chemical processing plants.

4、Increasing Mechanical Strength:

The addition of potassium fluoride to glass compositions can enhance the mechanical strength of the final product. This improvement in strength and durability is beneficial for protective glasses, such as those used in safety goggles, bulletproof windows, and other impact-resistant applications.

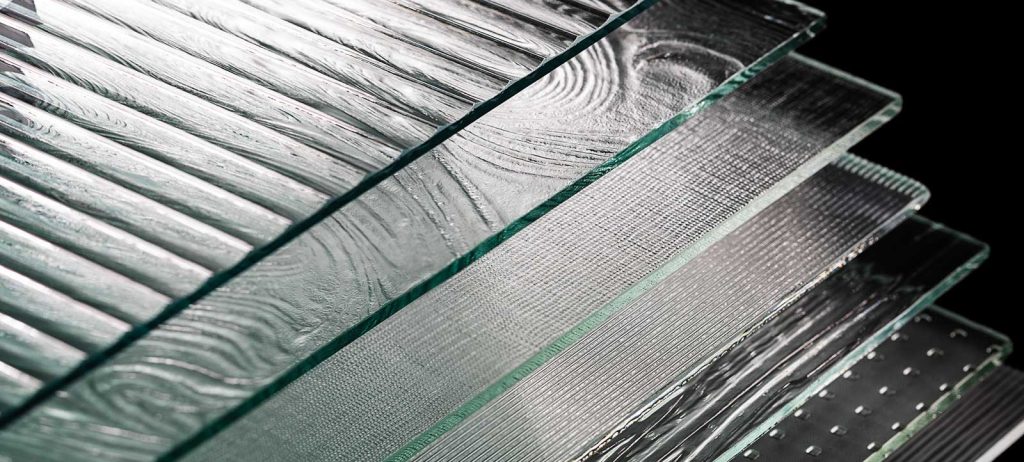

5、Improving Homogeneity and Transparency:

Potassium fluoride acts as a flux, promoting the homogenous mixing of raw materials during the melting process. This homogeneity results in glass with fewer defects, such as bubbles and inclusions, which are critical for applications requiring high transparency and optical precision.

6、Reducing Viscosity:

By lowering the viscosity of the molten glass, potassium fluoride facilitates easier shaping and forming of glass articles. This property is essential in the production of complex shapes and fine details, such as those required in specialty glassware and high-precision optical components.

Advantages of Using Potassium Fluoride in Specialty Glass Manufacturing

1、Energy Efficiency:

The reduction in melting temperature achieved by adding potassium fluoride translates into significant energy savings during the glass melting process. Lower energy requirements not only reduce operational costs but also minimize the environmental impact of glass production.

2、Enhanced Product Performance:

Glass products containing potassium fluoride exhibit superior performance in terms of optical clarity, chemical resistance, and mechanical strength. These enhanced properties expand the range of applications for specialty glass and improve the quality and reliability of the final products.

3、Process Flexibility:

The ability to modify the glass composition with potassium fluoride provides manufacturers with greater flexibility in designing glass with specific properties. This flexibility is crucial for meeting the diverse and evolving demands of industries such as aerospace, electronics, and medical devices.

4、Quality Control:

The homogeneous mixing promoted by potassium fluoride helps in achieving consistent quality in glass production. Fewer defects and uniform properties across batches ensure high standards of quality control, which is essential for critical applications.

5、Cost-Effectiveness:

Although the initial cost of potassium fluoride may be higher compared to other fluxes, the overall cost-effectiveness is realized through energy savings, reduced waste, and improved product performance. The long-term benefits of using potassium fluoride outweigh the initial investment, making it a cost-effective choice for specialty glass manufacturing.

Potassium fluoride is a vital component in the manufacturing of specialty glass, offering numerous benefits that enhance the properties and performance of the final product. Its ability to lower the melting point, improve optical and chemical properties, increase mechanical strength, and promote homogeneity makes it an indispensable material in the glass industry. The advantages of energy efficiency, enhanced product performance, process flexibility, quality control, and cost-effectiveness further underscore its importance. As the demand for high-performance glass continues to grow, the role of potassium fluoride in specialty glass manufacturing will remain crucial, driving innovation and excellence in this field.

By leveraging the unique properties of potassium fluoride, manufacturers can produce specialty glass that meets the stringent requirements of advanced applications, ensuring reliability, durability, and superior performance.