The Magic of Sodium Bifluoride in Metal Treatment: Cleaning, Etching, and Enhancement

Sodium bifluoride (NaHF2) is a powerful chemical compound with a wide range of applications, primarily in the realm of metal cleaning and etching processes. It plays a vital role in enhancing the quality and adhesion of various metals, such as aluminum, titanium, magnesium, and steel. In this article, we will explore the applications of sodium bifluoride in these processes and the underlying principles that make it so effective.

Applications of Sodium Bifluoride in Metal Cleaning and Etching

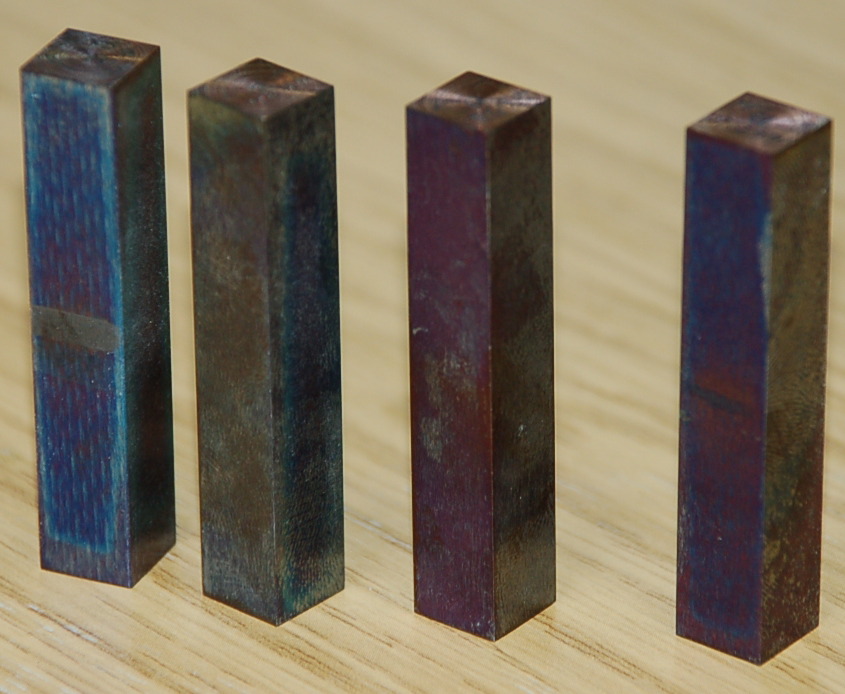

1. Aluminum:Aluminum is a widely used metal in various industries due to its lightweight and corrosion-resistant properties. However, aluminum can develop an oxide layer on its surface that hampers adhesion and can affect its appearance. Sodium bifluoride is used to remove the oxide layer from aluminum surfaces, making them more receptive to subsequent treatments, such as coating or welding.In certain applications, sodium bifluoride is used for etching aluminum to create specific surface patterns, enhancing its adhesion properties.

2. Titanium:Titanium is known for its excellent corrosion resistance and high strength-to-weight ratio, making it valuable in industries like aerospace and medical devices. Similar to aluminum, sodium bifluoride is used to eliminate oxide layers from titanium surfaces, preparing them for further processing.In specialized applications, sodium bifluoride is employed for controlled etching, which can be used for texturing the titanium surface for various purposes.

3. Magnesium:Magnesium is a lightweight metal used in industries like automotive and aerospace. However, it is susceptible to oxidation, which can affect its surface quality.Sodium bifluoride effectively removes oxide layers on magnesium surfaces, improving their appearance and adhesion properties.In some cases, sodium bifluoride is used to etch magnesium surfaces for specific applications.

4. Steel:Steel is a widely used material in construction, manufacturing, and numerous other industries. Sodium bifluoride can help eliminate oxide layers and contaminants on steel surfaces, enhancing their cleanliness and adhesion properties.

Application Principles

1. Oxide Removal

Sodium bifluoride's effectiveness in oxide removal lies in its strong acidic nature. When sodium bifluoride is in contact with the oxide layer, it reacts with it through the following chemical reaction:

Oxide + NaHF2 → Metal Fluoride + Water

Here, the oxide is converted into a metal fluoride, which is water-soluble and easily removed. As a result, the metal surface underneath is exposed, free from oxide and contaminants. This enhanced surface is then ready for further processing, such as coating, welding, or any other desired application.

2. Etching

Sodium bifluoride can be used for etching purposes, particularly when controlled surface texturing is required. In this case, sodium bifluoride's etching capability comes from its ability to react with the metal surface, selectively removing layers to create desired patterns or textures.

Sodium bifluoride is a valuable chemical compound with a significant impact on metal cleaning and etching processes. It aids in removing oxide layers, contaminants, and unwanted substances from metal surfaces, thereby enhancing their quality, adhesion, and suitability for various applications. Understanding the applications and principles behind sodium bifluoride's use in these processes is essential for the industries and applications that rely on the quality of their metal surfaces.

- Fluoride Salt

- Ammonium Fluoride

- Sodium Fluoride

- Potassium Fluoride

- Sodium Hydrogenfluoride

- Potassium Bifluoride

- Magnesium Fluoride

- Aluminium Fluoride

- Barium Fluoride

- Lithium Fluoride

- Strontium Fluoride

- Nickel Fluoride

- Zinc Fluoride