The Use of Magnesium fluoride in Thin Films

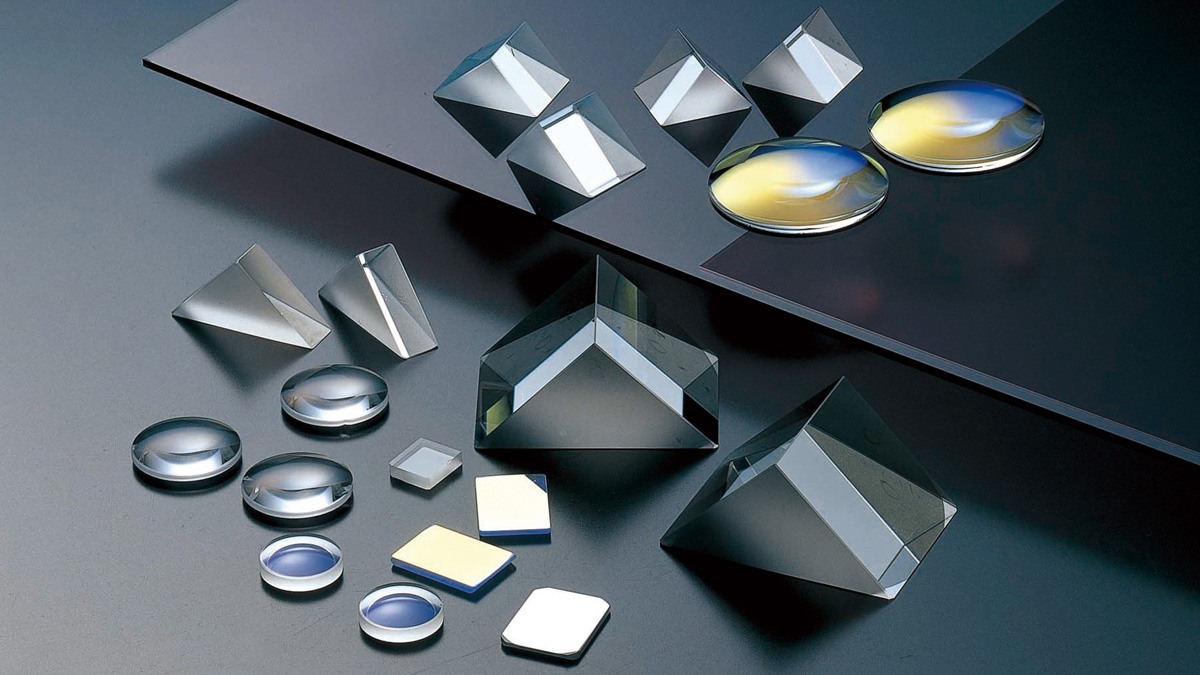

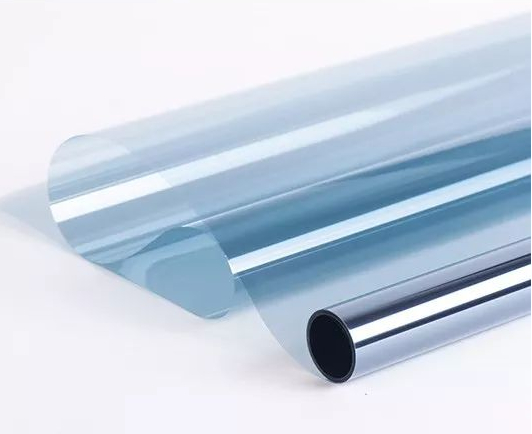

In the realm of optical components, surface reflection can lead to a significant loss of light energy which can hamper the overall performance of the optical system. To address this concern, a transparent dielectric film is frequently applied to the surface of the optical component. This anti-reflection coating works by reducing the intensity of reflected light and boosting the intensity of transmitted light. This, in turn, leads to sharper imaging, better contrast, and more efficient optical system performance.

Magnesium fluoride is a highly sought-after material in the world of anti-reflection coating. This fantastic crystal, with its off-white hue, possesses positive birefringence and incredible resistance to mechanical and thermal shock, not to mention radiation. What sets this kind of fluoride chemical apart even further is its broad transmission range of light, spanning from a mere 120 nm in the deep ultraviolet band all the way to an impressive 7,000 nm in the far infrared band. With such incredible qualities, it's no wonder that magnesium fluoride is a beloved and versatile optical functional crystal material that is frequently implemented in the development of magnesium fluoride films for various optical coatings.

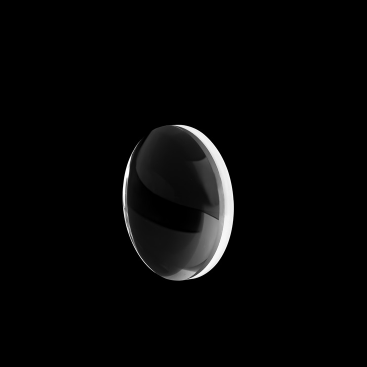

1、Use as lens material

Magnesium fluoride is a highly popular material for thin film coatings on glass substrates owing to its near-perfect refractive index and exceptional stability. Not only does it enhance transparency and reduce reflection, but it also offers wear and chemical resistance, making it the ideal choice for safeguarding sensitive glass-based technologies such as sensors, goggles, heat reflective windows, LEDs, and liquid crystal displays. Interestingly, by using varied temperatures, film thicknesses, and layering techniques, it is possible to create MgF2/Ag-doped photonic crystals for exact frequency adjustment of transmission bands. All in all, magnesium fluoride is a versatile and effective material that is indispensable for various applications in the world of optics and electronics.

2、Use in the fabrication of Cu-MgF2 nanoceramic films

By utilizing the vacuum evaporation technique, our researchers have successfully developed innovative Cu-MgF2 nanoceramic films. These films possess highly uniform fcc-Cu grain structures and amorphous MgF2 matrices, which creates an average particle size of 14-16nm. What makes these nanoceramic films truly unique is their exceptional light absorption selectivity and impressive nonlinear optical effects. These characteristics make them highly versatile and suitable for a wide range of advanced applications.

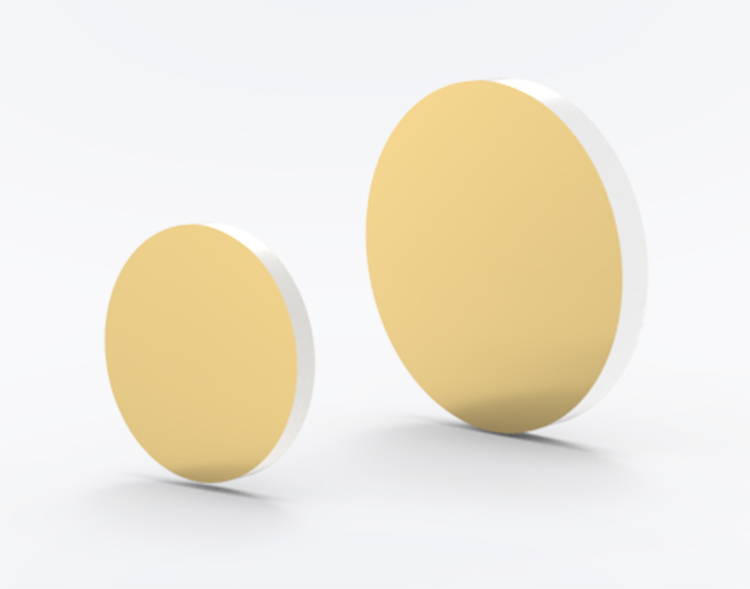

3、Use as protective film for metal reflectors

It is commonly understood that highly-reflective mirror materials, such as aluminum, silver, and gold, possess a myriad of drawbacks, such as poor mechanical and chemical stability, softness, and susceptibility to oxidation. Nonetheless, our advanced technology remedies these issues by applying a highly durable protective layer of magnesium fluoride onto the surface of aluminum mirrors, thereby ensuring that these mirrors attain superior protection while retaining their highly-reflective properties. In the realm of advanced optical devices, particularly in space-based UV remote sensors applications, this technology has been widely adopted, as it effectively resolves many of the common vulnerabilities that are prevalent in silver-based reflective film systems.

- Fluoride Salt

- Ammonium Fluoride

- Sodium Fluoride

- Potassium Fluoride

- Sodium Hydrogenfluoride

- Potassium Bifluoride

- Magnesium Fluoride

- Aluminium Fluoride

- Barium Fluoride

- Lithium Fluoride

- Strontium Fluoride

- Nickel Fluoride

- Zinc Fluoride