Unveiling the Multifaceted Role of Ammonium Fluoroborate in Metal Processing

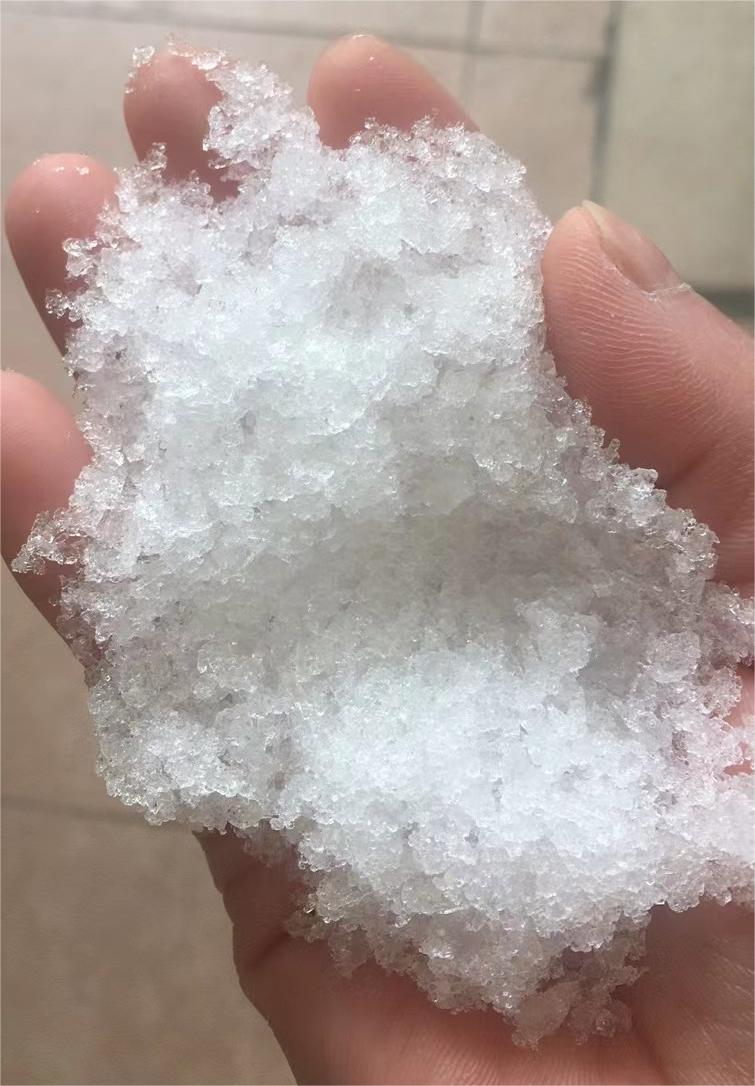

Ammonium fluoroborate (NH₄BF₄) stands as a testament to the remarkable versatility of chemical compounds in industrial applications, particularly in the realm of metal processing. With its unique chemical properties, this compound plays a pivotal role in various stages of metal treatment, contributing to the enhancement of metal properties and the creation of superior products. In this article, we embark on a journey to explore the multifaceted nature of ammonium fluoroborate and its diverse applications in the fascinating world of metallurgy.

Chemical Characteristics of Ammonium Fluoroborate:

1、Ionic Structure: At its core, ammonium fluoroborate comprises ammonium cations (NH₄⁺) and fluoroborate anions (BF₄⁻). This ionic structure confers unique properties to the compound, facilitating its interaction with diverse chemical species and substrates.

2、Water Solubility: One of the defining features of NH₄BF₄ is its high solubility in water, a property exploited in various aqueous-based processes. This solubility enables facile preparation of solutions, ensuring uniform distribution and effective utilization in industrial applications.

3、Fluoride Ion Source: Within aqueous environments, ammonium fluoroborate readily dissociates to release fluoride ions (F⁻). These fluoride ions play pivotal roles in surface modification processes, such as metal etching and corrosion protection, by forming stable fluorinated layers on substrates.

4、Acidic Behavior: The presence of fluoride ions imparts acidic characteristics to ammonium fluoroborate solutions. This acidity influences reaction kinetics and catalyzes certain chemical transformations, particularly in metal surface treatments and electroplating processes.

5、Thermal Stability: NH₄BF₄ exhibits notable thermal stability, making it suitable for applications involving elevated temperatures. Its resilience to thermal decomposition ensures consistent performance and reliability in heat-intensive processes.

6、Complexation Properties: Ammonium fluoroborate has a propensity to form complexes with metal ions, organic ligands, and other chemical species. This complexation behavior finds application in various analytical techniques, metal extraction processes, and catalytic reactions.

Applications Across Industries:

1. Annealing:

In annealing processes, ammonium fluoroborate serves as a surface activation agent. Prior to annealing, metal surfaces are treated with ammonium fluoroborate solutions to remove oxides and contaminants, ensuring a clean substrate for subsequent heat treatment. This surface activation step promotes uniform heating and facilitates the diffusion of alloying elements, leading to desired microstructural changes and improved mechanical properties in the annealed metal.

2. Brazing and Soldering:

Ammonium fluoroborate functions as a fluxing agent in brazing and soldering applications. Fluxes containing NH₄BF₄ are applied to metal surfaces to facilitate the wetting and flow of molten filler metals. The flux reacts with surface oxides, promoting their dissolution and preventing their reformation during the joining process. This ensures strong metallurgical bonds between the base metal and the filler material, resulting in high-quality joints with minimal defects.

3. Hardening and Quenching:

During hardening processes such as martensitic hardening, ammonium fluoroborate quenching media. Metal components heated to critical temperatures are rapidly immersed in ammonium fluoroborate solutions to achieve controlled cooling rates. The rapid quenching rate suppresses the formation of undesired phases and promotes the formation of martensite, resulting in increased hardness and improved mechanical properties in the treated metal.

4. Surface Protection:

Ammonium fluoroborate is utilized for surface protection in various metal heat treatment applications. Treatment with NH₄BF₄ solutions forms a thin, protective fluoride-rich layer on the metal surface, providing resistance against corrosion and oxidation. This protective coating enhances the durability and longevity of metal components exposed to corrosive environments, extending their service life and minimizing maintenance requirements.

5. Controlled Atmosphere Heat Treatment:

In controlled atmosphere heat treatment processes, ammonium fluoroborate can be employed as a component in gas quenching systems. By introducing ammonium fluoroborate vapor into the quenching environment, controlled cooling rates can be achieved, preventing distortion and minimizing residual stresses in heat-treated components. This approach ensures dimensional accuracy and maintains tight tolerances in precision-engineered parts.

The diverse applications of ammonium fluoroborate in metal heat treatment underscore its versatility and significance in the manufacturing industry. From surface activation to brazing, quenching, and surface protection, NH₄BF₄ plays a crucial role in optimizing metallurgical processes and improving the performance of metal components. As advancements in materials science continue to drive innovation, the utility of NH₄BF₄ in metal heat treatment remains indispensable, offering tailored solutions to meet the evolving demands of modern engineering and manufacturing.