Celestial Brilliance: The Enigmatic Role of Sodium Hexafluorosilicate in Porcelain Enamel

Sodium hexafluorosilicate, also known as sodium silicofluoride, is a fascinating chemical compound with a wide range of applications. One of its most prominent uses is in the realm of porcelain enamel, where it plays a crucial role in enhancing the durability and aesthetics of various products. In this article, we will delve into the principles behind the application of sodium hexafluorosilicate in porcelain enamel and explore the extensive scope of its usage in different industries.

Understanding Sodium Hexafluorosilicate

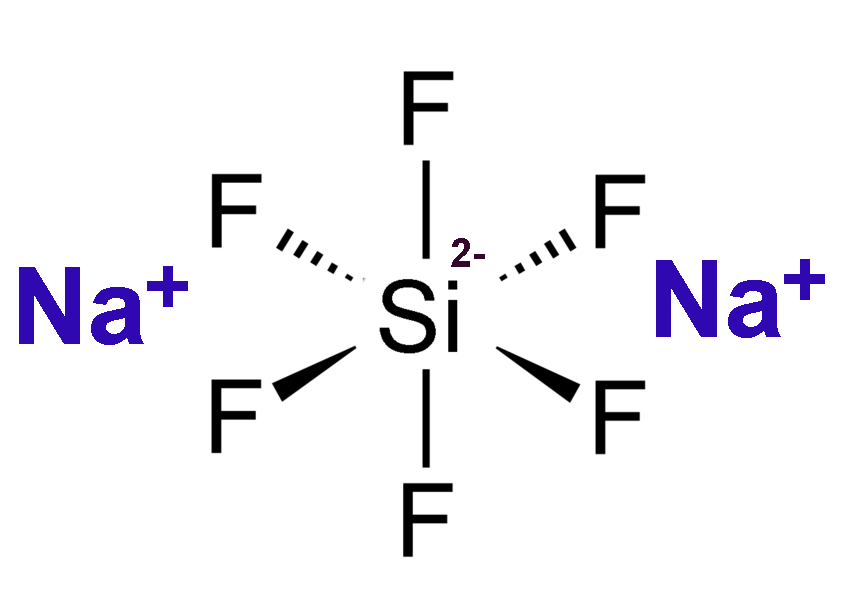

Sodium hexafluorosilicate is a synthetic inorganic compound with the chemical formula Na2SiF6. It is a white crystalline solid that is highly soluble in water and has a variety of industrial applications. This compound is derived from the reaction between sodium fluoride (NaF) and silicon dioxide (SiO2) under controlled conditions. The resulting product, sodium hexafluorosilicate, possesses unique properties that make it suitable for a multitude of applications.

The Application Principles in Porcelain Enamel

Porcelain enamel, often referred to as vitreous enamel, is a type of glass coating applied to various materials, including metal, glass, and ceramics. The primary purpose of using porcelain enamel is to enhance the appearance, corrosion resistance, and durability of the underlying material. Sodium hexafluorosilicate finds its way into porcelain enamel formulations due to its ability to improve several key properties of the enamel:

1、Fluxing Agent: Sodium hexafluorosilicate serves as a fluxing agent in porcelain enamel. A flux is a substance that lowers the melting temperature of the enamel and facilitates the formation of a smooth and durable glass coating. This is achieved by reducing the viscosity of the enamel at lower temperatures, allowing it to flow evenly over the substrate.

2、Increased Chemical Resistance: The incorporation of sodium hexafluorosilicate enhances the chemical resistance of porcelain enamel. It helps the enamel withstand exposure to acids, alkalis, and various corrosive substances, making it an ideal choice for applications where chemical resistance is vital, such as in chemical tanks and laboratory equipment.

3、Enhanced Adhesion: Proper adhesion of enamel to the substrate is crucial to ensure the longevity of the coated material. Sodium hexafluorosilicate promotes adhesion by facilitating the formation of a strong bond between the enamel and the substrate. This bond helps prevent chipping, peeling, or cracking of the enamel over time.

4、Aesthetic Improvement: The addition of sodium hexafluorosilicate can lead to improved aesthetics of the enamel coating. It can enhance the clarity and brilliance of colors, making porcelain enamel a popular choice for decorative applications, such as cookware, signage, and artistic designs.

Applications in Porcelain Enamel

The application of sodium hexafluorosilicate in porcelain enamel is vast, spanning across numerous industries and product categories. Some of the prominent applications include:

1、Cookware and Appliances: Porcelain enamel-coated cookware, such as pots, pans, and ovenware, benefits from the chemical and thermal resistance of sodium hexafluorosilicate-infused enamel. It ensures that the cookware can withstand high temperatures, resist staining, and maintain its appearance over time.

2、Sanitary Ware: Bathroom fixtures like sinks, bathtubs, and toilets are often coated with porcelain enamel containing sodium hexafluorosilicate. This not only enhances the visual appeal of these products but also ensures they remain durable and easy to clean.

3、Architectural Cladding: Porcelain enamel is used as an architectural cladding material for buildings. Its weather resistance and color retention properties, boosted by sodium hexafluorosilicate, make it a sustainable choice for external façades.

4、Signage and Advertising: Outdoor signs and billboards employ porcelain enamel coatings for their long-lasting appearance. The addition of sodium hexafluorosilicate enhances the enamel's resistance to UV radiation, ensuring that colors remain vibrant for extended periods.

5、Laboratory Equipment: Porcelain enamel is often used to coat laboratory sinks, countertops, and fume hoods. The chemical resistance provided by sodium hexafluorosilicate is invaluable in maintaining the integrity of these critical components.

6、Artistic and Decorative Pieces: Porcelain enamel artists leverage the improved adhesion and color vibrancy offered by sodium hexafluorosilicate to create stunning and enduring artworks.

7、Automotive Parts: In the automotive industry, sodium hexafluorosilicate-enriched porcelain enamel is applied to exhaust systems, mufflers, and various underbody components to provide corrosion resistance and thermal stability.

8、Household Appliances: The surface of household appliances like refrigerators, ovens, and dishwashers is often coated with porcelain enamel to improve their appearance and durability.

Sodium hexafluorosilicate, when incorporated into porcelain enamel formulations, significantly enhances the quality and functionality of a wide array of products across diverse industries. Its role as a fluxing agent, combined with its ability to improve chemical resistance, adhesion, and aesthetic appeal, makes it a sought-after ingredient for enamel coating applications. From cookware to architectural cladding, and from laboratory equipment to artistic creations, sodium hexafluorosilicate has established itself as a key component in creating enduring and visually pleasing enamel-coated products. Its contribution to the longevity and performance of these products underscores its importance in various manufacturing processes and artistic endeavors.