How does magnesium fluorosilicate help improve the properties of aluminum alloys?

Aluminum alloys are ubiquitous in modern industries, serving as vital components in automotive manufacturing, aerospace engineering, construction, and beyond. Their versatility, lightweight nature, and remarkable strength-to-weight ratio make them indispensable. However, achieving optimal properties in aluminum alloys requires meticulous attention to detail during production, and one crucial ingredient that significantly enhances their characteristics is magnesium fluorosilicate.

Understanding the Role of Magnesium Fluorosilicate

Magnesium fluorosilicate acts as a potent grain refiner and degasser in the production of aluminum alloys. But what exactly does this mean for the properties of these alloys?

1. Grain Refinement:

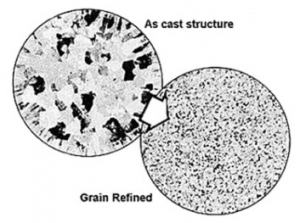

Magnesium fluorosilicate plays a pivotal role in refining the grain structure of aluminum alloys. By promoting the formation of fine, uniform grains, it enhances mechanical properties such as strength, ductility, and toughness. Additionally, finer grains result in improved surface finish and enhanced machinability, contributing to greater versatility in applications.

2. Deoxidation and Degassing:

Impurities like oxygen and hydrogen can compromise the integrity of aluminum alloys. Magnesium fluorosilicate acts as a powerful degassing agent, facilitating the removal of dissolved hydrogen and other gases from the molten aluminum. Moreover, it aids in deoxidizing the melt, preventing the formation of undesirable inclusions and ensuring the purity of the alloy.

3. Casting Properties Improvement:

The presence of magnesium fluorosilicate enhances the casting properties of aluminum alloys. It leads to reduced porosity and improved castability, resulting in components with superior quality and integrity. This makes the alloys particularly suitable for intricate castings and high-performance applications.

4. Enhanced Mechanical Properties:

Through its grain refining and impurity-removing capabilities, magnesium fluorosilicate contributes to a significant enhancement in the mechanical properties of aluminum alloys. These alloys exhibit increased tensile strength, improved fatigue resistance, and superior elongation characteristics, making them ideal for demanding environments and critical structural applications.

Applications and Implications

The utilization of magnesium fluorosilicate in aluminum alloy production opens up a world of possibilities across various industries:

● Automotive Industry: Lighter yet stronger aluminum alloys contribute to fuel efficiency and performance, leading to the production of more sustainable vehicles.

● Aerospace Engineering: Enhanced mechanical properties ensure the safety and reliability of aircraft components, where every ounce matters.

● Construction Sector: Aluminum alloys fortified with magnesium fluorosilicate offer durability, corrosion resistance, and design flexibility for architectural and structural applications.

In essence, magnesium fluorosilicate serves as a catalyst for innovation and advancement in aluminum alloy technology. Its ability to refine grain structures, remove impurities, and enhance mechanical properties is paramount in elevating the performance and reliability of aluminum alloys across diverse applications. As industries continue to push the boundaries of what's possible, magnesium fluorosilicate stands as a cornerstone in the quest for excellence in material science and engineering.

- Fluoride Salt

- Ammonium Fluoride

- Sodium Fluoride

- Potassium Fluoride

- Sodium Hydrogenfluoride

- Potassium Bifluoride

- Magnesium Fluoride

- Aluminium Fluoride

- Barium Fluoride

- Lithium Fluoride

- Strontium Fluoride

- Nickel Fluoride

- Zinc Fluoride