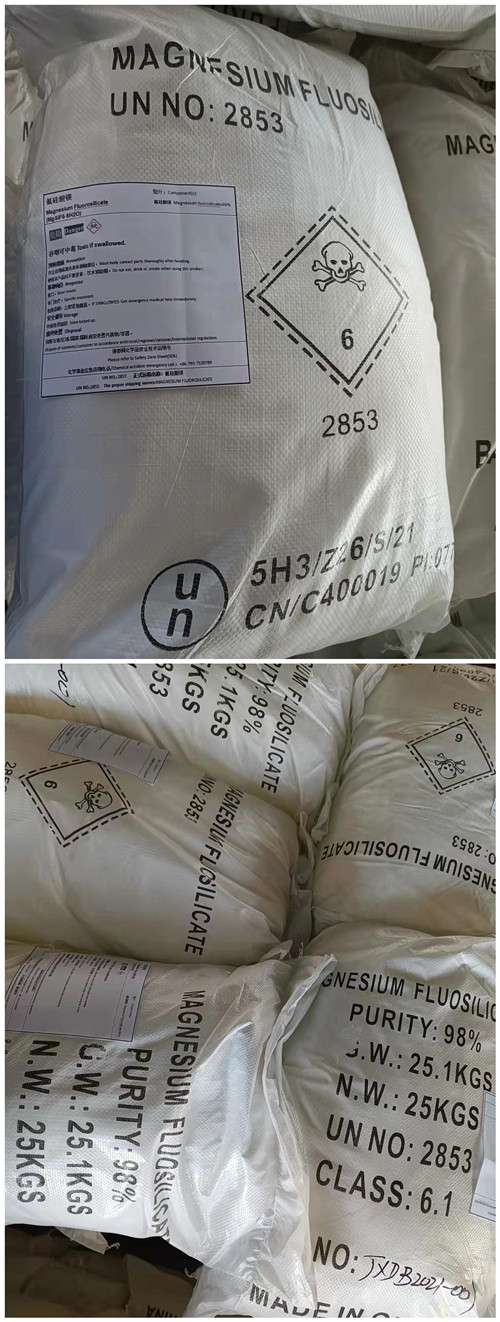

Magnesium Fluorosilicate-in cement floors

Magnesium Fluorosilicate also called Cement Hardener or Cement Curing Agent, which is widely used in new and old cement floors. The magnesium fluorosilicate can penetrate into the cement floor, and then undergo a complex chemical reaction with the free calcium in the cement floor. The resulting calcium silicate substance can fill and block a large number of pores in the cement floor itself, making it a dense Overall, and greatly improve the performance of the cement floor.

After the cement floor is applied with Magnesium fluorosilicate (cement curing agent), the hardness, strength, abrasion resistance, acid and alkali resistance, impact resistance, water resistance, impermeability and other properties have been greatly improved, especially the hardness, from level 4 to level 8. , Coupled with the improvement of abrasion resistance and impact resistance, the cement floor can be more suitable for underground garages, factory workshops and other places. The most surprising thing is that the service life of the cement-cured floor has reached more than 30 years, so that the cement-cured floor can avoid a lot of unnecessary ground repair and renovation work during use, and improve the efficiency of the floor.

The construction method of cement curing agent for cement floor is as follows:

First step: Clear the ground

Before the cement floor is constructed, the debris, dust, and pollutants on the floor need to be cleaned up to facilitate the penetration of the cement curing agent. If there are cracks and potholes on the ground, you should firstly use cement mortar to repair them, and then use a floor grinder to grind and level them.

Second step: Ground curing

Mix the Magnesium Fluorosilicate (cement curing agent) with water in a ratio of 1:3 to 1:5, and then apply the magnesium fluorosilicate evenly on the cement floor to allow it to penetrate evenly.

Third step: Secondary curing

After the cement floor surface is dry, perform secondary curing. Follow the steps above to apply cement curing agent.

Fourth step: Ground cleaning

After the cement floor is dry, remove the residual curing agent material on the cement floor, otherwise the curing agent material will form crystals on the cement floor.

Fifth step: Ground grinding

Use resin polishing pads to grind the cement-cured floor from 50 mesh to 3000 mesh. The ground cement-cured floor can have a high gloss and flatness, so that the cement-cured floor also has a certain decorative performance.

- Fluoride Salt

- Ammonium Fluoride

- Sodium Fluoride

- Potassium Fluoride

- Sodium Hydrogenfluoride

- Potassium Bifluoride

- Magnesium Fluoride

- Aluminium Fluoride

- Barium Fluoride

- Lithium Fluoride

- Strontium Fluoride

- Nickel Fluoride

- Zinc Fluoride