Potassium Fluoroaluminate: A Versatile Soldering Flux for All Your Welding Needs

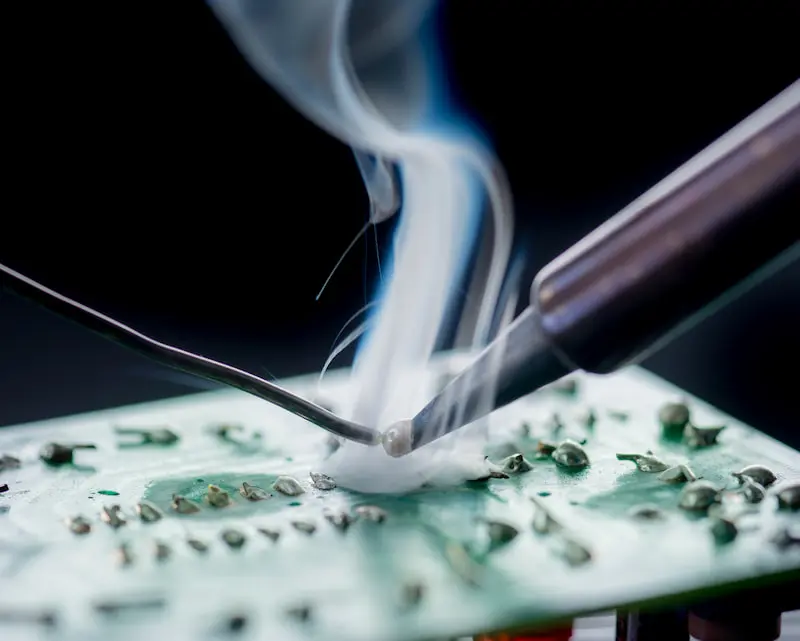

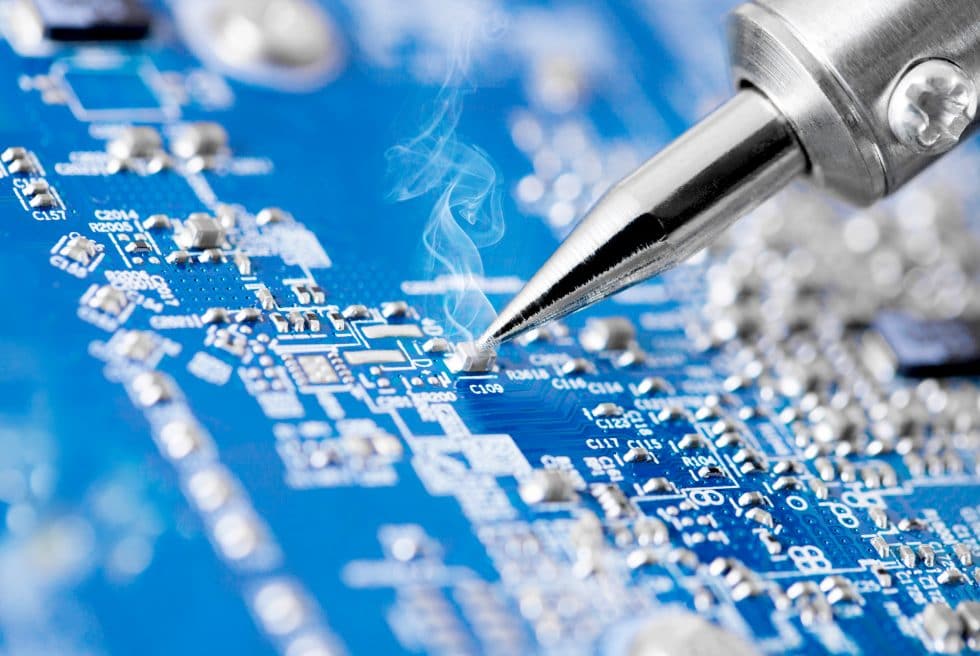

Soldering is a crucial process in various industries, from electronics to plumbing, and even jewelry making. It involves joining two metal components by melting a filler material, usually solder, which forms a bond upon cooling. To ensure a strong and clean solder joint, a soldering flux is often used. One such flux that has gained popularity for its versatility and effectiveness is potassium fluoroaluminate. In this article, we will explore what potassium fluoroaluminate is and how it is used as a soldering flux.

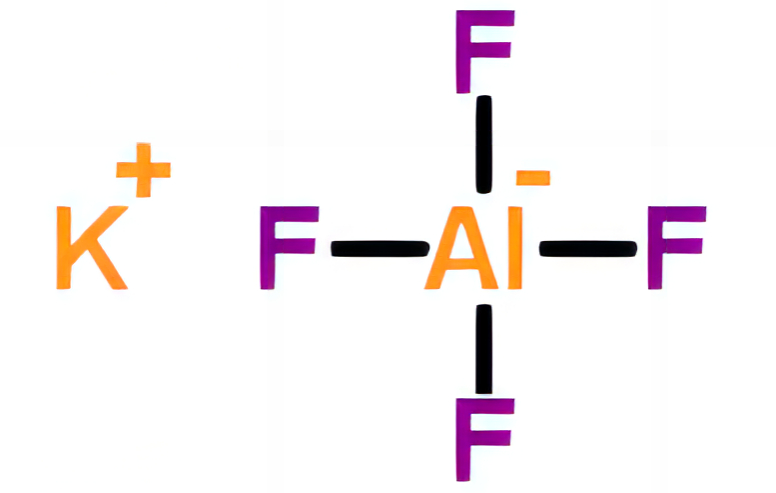

What is Potassium Fluoroaluminate?

Potassium fluoroaluminate, also known as KAlF4, is a synthetic inorganic compound. It is a white crystalline powder with the chemical formula K3AlF6 and is primarily composed of potassium, aluminum, and fluorine. This unique compound offers exceptional properties that make it an ideal choice for various soldering applications.

Potassium fluoroaluminate is composed of potassium (K), aluminum (Al), and fluorine (F) atoms, arranged in a crystal lattice structure. This structure is a key factor in its effectiveness as a soldering flux. The compound's chemical composition and lattice structure allow it to facilitate the soldering process by removing oxides from metal surfaces and protecting them from re-oxidation during soldering.

How Potassium Fluoroaluminate Works as a Soldering Flux

Soldering fluxes play a critical role in the soldering process by performing several key functions:

1、Removal of Oxides

One of the primary functions of a soldering flux is to remove oxides from the metal surfaces to be soldered. Oxides can inhibit the formation of a strong and reliable bond between the solder and the base metal. Potassium fluoroaluminate excels in this regard because its composition allows it to react with oxides, effectively deoxidizing the surfaces.

2、Prevention of Oxide Reformation

Potassium fluoroaluminate not only removes existing oxides but also forms a protective layer on the metal surface, preventing new oxides from forming during the soldering process. This protective layer helps maintain a clean and oxide-free surface for the solder to bond with.

3、Wetting

Wetting is the ability of the solder to flow evenly and adhere to the metal surfaces being joined. Potassium fluoroaluminate enhances the wetting ability of the solder by reducing surface tension and allowing it to spread more evenly, resulting in a stronger and more reliable solder joint.

4、Dissolving Metal Impurities

In some cases, metal surfaces may contain impurities or contaminants that can interfere with the soldering process. Potassium fluoroaluminate has the unique capability to dissolve these impurities, ensuring a clean and reliable solder connection.

Applications of Potassium Fluoroaluminate in Soldering

Potassium fluoroaluminate is a versatile soldering flux used in various industries and applications. Let's explore some of its common uses:

Electronics Soldering

In the electronics industry, precise and reliable soldering is essential for manufacturing electronic components and circuit boards. Potassium fluoroaluminate is often used as a flux for soldering components such as surface-mount devices (SMDs), through-hole components, and wires. Its ability to remove oxides and promote wetting ensures high-quality solder joints in electronic assemblies.

Plumbing and Pipe Soldering

Potassium fluoroaluminate is widely employed in plumbing and pipe soldering applications. When joining copper pipes or fittings, this flux ensures clean and leak-free connections. Its deoxidizing properties are particularly valuable in preventing the buildup of oxides in plumbing systems.

Jewelry Making

Jewelry artisans use soldering to create intricate and delicate pieces. Potassium fluoroaluminate is a preferred flux for jewelry soldering as it helps achieve precise solder joints with minimal discoloration. The protective layer it forms ensures that the jewelry's appearance remains untarnished.

Automotive and Aerospace

In the automotive and aerospace industries, where high-performance solder joints are critical, potassium fluoroaluminate is used for various applications, including joining electrical connections, fuel systems, and hydraulic components. Its ability to prevent oxidation and promote wetting is essential for ensuring safety and reliability in these applications.

Advantages of Using Potassium Fluoroaluminate

1、One of the primary advantages of using potassium fluoroaluminate as a soldering flux is its effectiveness in removing oxides, preventing reoxidation, and promoting wetting. This results in strong and reliable solder joints.

2、Potassium fluoroaluminate is compatible with various metals, making it suitable for a wide range of soldering applications. It can be used with metals like copper, brass, aluminum, and even some alloys.

3、After soldering, potassium fluoroaluminate leaves minimal residue. This is advantageous in applications where post-solder cleaning may be challenging or undesirable, such as electronics and jewelry making.

4、Potassium fluoroaluminate has a long shelf life when stored properly, making it a cost-effective choice for industries that may not use soldering fluxes on a daily basis.

Potassium fluoroaluminate is a valuable soldering flux with a wide range of applications. Its ability to remove oxides, prevent reoxidation, promote wetting, and dissolve impurities makes it an indispensable tool for achieving strong and reliable solder joints. Whether you are soldering electronic components, plumbing fixtures, jewelry, or other metal components, potassium fluoroaluminate can help you achieve high-quality results. As with any soldering operation, it is essential to follow safety guidelines and best practices to ensure a successful and safe soldering process. So, the next time you pick up your soldering iron, consider using potassium fluoroaluminate to make your soldering work easier and more effective.