Sodium Fluoride as a Setting Accelerator: Applications and Insights

Sodium fluoride, a chemical compound that you might associate with dental hygiene, actually plays a significant role in various industries beyond oral care. One of its lesser-known but crucial applications is as a setting accelerator, especially in the world of ceramics and glass production. In this article, we'll delve into the science behind sodium fluoride's role as a setting accelerator and explore the diverse areas where it finds practical use.

What Is Sodium Fluoride?

Sodium fluoride (NaF) is a simple chemical compound consisting of sodium (Na) and fluoride (F) ions. It is a white, crystalline solid that dissolves readily in water. While it's widely recognized for its use in toothpaste and water fluoridation, its versatility extends to many other industrial applications.

Sodium Fluoride as a Setting Accelerator

In the realm of ceramics and glass manufacturing, sodium fluoride is employed as a setting accelerator. A setting accelerator is a substance that speeds up the process of solidification or hardening of materials. Here's how sodium fluoride achieves this:

a、Lowering Melting Points

One of the primary ways sodium fluoride accelerates the setting process is by lowering the melting points of certain materials, such as glass and ceramic compounds. By doing so, it makes these materials more amenable to shaping and molding during manufacturing processes.

b、Enhanced Flowability

Sodium fluoride increases the flowability of molten glass or ceramic materials. This improved fluidity allows for better distribution of materials in molds, resulting in a more uniform and refined final product.

c、Reduction of Energy Consumption

By reducing the temperature at which materials can be processed, sodium fluoride helps cut down energy consumption during production. This not only saves costs but also has environmental benefits.

Applications of Sodium Fluoride as a Setting Accelerator

Now that we understand how sodium fluoride works as a setting accelerator, let's explore the various applications where it is used:

a. Glass Manufacturing

Sodium fluoride is a crucial component in the production of various types of glass, including optical glass, window glass, and specialty glass. It lowers the melting point of silica (the primary component of glass), improving its workability and transparency.

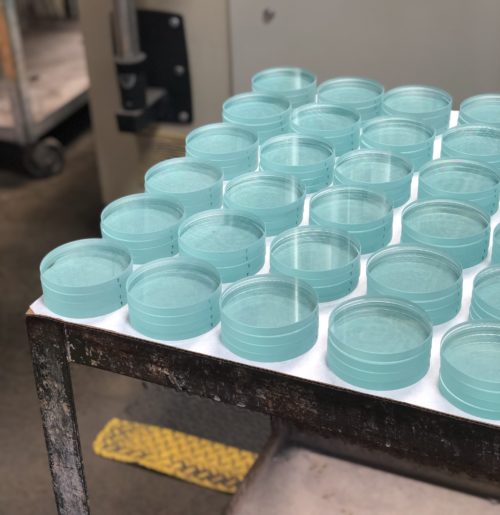

b. Ceramic Production

In the ceramic industry, sodium fluoride is often added to ceramic materials like porcelain and tiles. It facilitates the shaping and hardening processes, leading to stronger and more durable ceramic products.

c. Optical Lenses

The world of optics relies heavily on sodium fluoride as a setting accelerator. It aids in the manufacturing of high-quality optical lenses, such as camera lenses, microscopes, and telescopes, by ensuring precise shaping and quick solidification.

d. Glass Fiber Reinforced Plastics (GFRP):

Sodium fluoride contributes to the production of GFRP, commonly known as fiberglass. GFRP is used in a wide range of applications, including boat building, automotive components, and construction materials, due to its strength, durability, and corrosion resistance.

e. Coatings and Thin Films

In the field of thin-film deposition, sodium fluoride is utilized as a setting accelerator. It improves the adherence and smoothness of thin films on various substrates, enhancing the performance of optical coatings, solar panels, and semiconductor devices.

Sodium fluoride's role as a setting accelerator in ceramics and glass production is a prime example of how chemistry and materials science contribute to the advancement of various industries. Its ability to lower melting points, improve flowability, and reduce energy consumption has made it an indispensable component in the creation of high-quality glass, ceramics, and optical products. As we continue to explore innovative applications for sodium fluoride, we can look forward to further advancements in these fields and beyond, driven by the subtle but powerful chemistry of this versatile compound.