Utilizing Magnesium Fluorosilicate in the Ceramics Industry

Ceramics have been an integral part of human history, dating back thousands of years to ancient civilizations. From pottery to modern advanced ceramics, these versatile materials have evolved significantly. One critical ingredient that has contributed to these advancements is magnesium fluorosilicate. In this article, we will explore how magnesium fluorosilicate is used in the ceramics industry, its properties, and its role in enhancing the performance and durability of ceramic products.

Understanding Magnesium Fluorosilicate

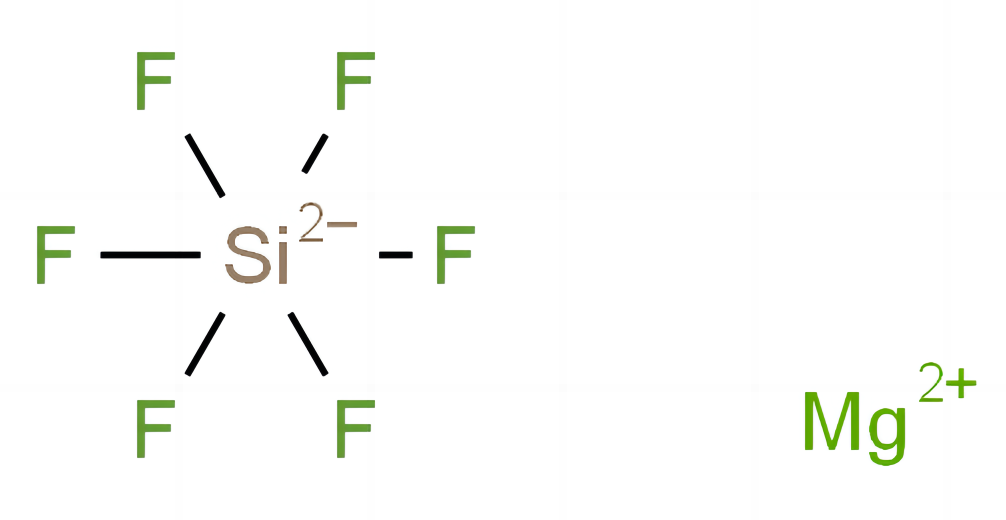

Magnesium fluorosilicate, also known as magnesium hexafluorosilicate or MgSiF6, is a chemical compound composed of magnesium (Mg), silicon (Si), and fluorine (F).It typically appears as a white powder or crystal and has various industrial applications due to its unique properties.

Properties of Magnesium Fluorosilicate

● High Melting Point: Magnesium fluorosilicate boasts a high melting point, making it suitable for use in high-temperature applications. This property is particularly valuable in ceramics production, where extreme heat is often required to mold and shape ceramic materials.

● Fluxing Agent: In ceramics, fluxing agents are substances that lower the melting point of other materials, promoting fusion and ensuring the clay components bond together efficiently. Magnesium fluorosilicate serves as an effective fluxing agent, facilitating the vitrification process during firing.

Applications in the Ceramics Industry

1、Glaze Formulation

One of the primary applications of magnesium fluorosilicate in the ceramics industry is in glaze formulation. Glazes are the shiny, protective coatings applied to ceramics to enhance their appearance and durability. Magnesium fluorosilicate plays a crucial role in achieving the desired glaze characteristics:

a. Color Enhancement: Magnesium fluorosilicate can modify the color of glazes, giving them vibrant hues. This is particularly valuable in decorative ceramics, where vibrant colors are often desired.

b. Glossiness: The compound contributes to the glossy finish of glazes, enhancing the aesthetic appeal of ceramic products.

c. Resistance to Wear and Chemicals: Glazes containing magnesium fluorosilicate are more resistant to wear and chemical damage, increasing the longevity of ceramic products.

2、Refractory Materials

Refractory materials are essential in the ceramics industry because they can withstand extremely high temperatures without deforming or breaking down. Magnesium fluorosilicate is used as a refractory binder, helping to create highly heat-resistant ceramics for various applications, including kiln furniture, crucibles, and furnace linings.

3、Ceramic Insulators

In electrical and electronic industries, ceramic insulators are vital components for electrical transmission and distribution systems. Magnesium fluorosilicate is used to manufacture insulators with excellent electrical insulation properties, thermal stability, and resistance to environmental factors. These insulators are used in power lines, substations, and electrical equipment.

4、Structural Ceramics

The ceramics industry also benefits from magnesium fluorosilicate in the production of structural ceramics. These ceramics are engineered for mechanical strength, toughness, and resistance to wear. They find applications in cutting tools, bearings, and various industrial machinery components.

5、Ceramic Filters

Ceramic filters are used in various industrial processes, such as wastewater treatment and metal casting. Magnesium fluorosilicate is employed to create porous ceramic filters with controlled pore sizes. These filters efficiently remove impurities and contaminants from liquids and gases.

6、Ceramic Tiles

Magnesium fluorosilicate is utilized in the production of ceramic tiles, both for their aesthetic appeal and functional properties. It contributes to the formation of durable, low-porosity tiles that are resistant to stains and moisture, making them ideal for flooring, walls, and countertops.

Benefits of Using Magnesium Fluorosilicate

● Improved Durability: The addition of magnesium fluorosilicate enhances the durability and lifespan of ceramic products. It provides resistance to chemical corrosion, thermal shock, and mechanical wear and tear.

● Enhanced Aesthetics: The compound can modify the color and glossiness of ceramic glazes, allowing for a wide range of decorative options.

● High-Temperature Stability: Magnesium fluorosilicate's high melting point ensures that ceramics can maintain their structural integrity at elevated temperatures, making it valuable for applications in kilns and furnaces.

● Electrical Insulation: In electrical applications, ceramics containing magnesium fluorosilicate provide excellent electrical insulation, ensuring the safety and efficiency of electrical systems.

Magnesium fluorosilicate is a versatile and valuable component in the ceramics industry. Its ability to enhance the durability, aesthetics, and functionality of ceramics has made it indispensable in various applications, from glaze formulation to the production of refractory materials, insulators, structural ceramics, filters, and tiles. As technology continues to advance, magnesium fluorosilicate will likely play an even more significant role in pushing the boundaries of what ceramics can achieve in various industries. This unassuming compound truly exemplifies the saying that even the smallest ingredients can make a world of difference in the world of ceramics.