Applications of Potassium Fluotitanate as Grain Refiners in Industrial Processes

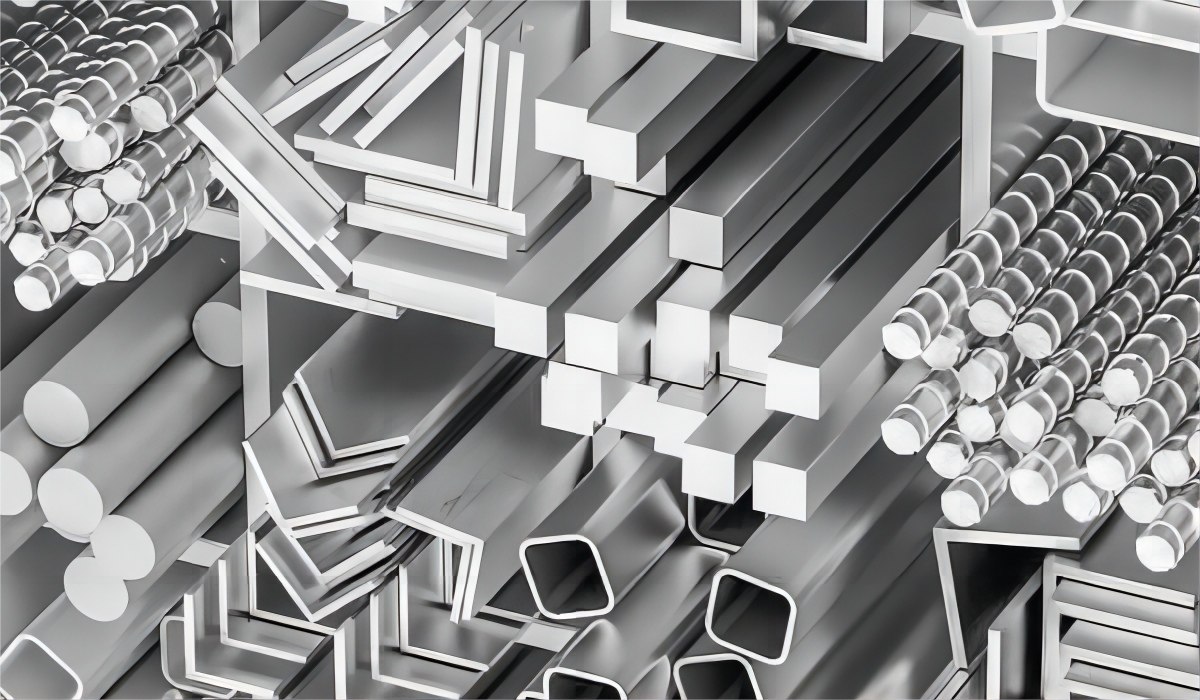

Potassium fluotitanate, a compound consisting of potassium, fluorine, and titanium, plays a crucial role in industrial applications as a grain refiner. This compound, commonly known as K2TiF6, is employed in various industries, particularly in metal casting processes, to enhance the structural properties of materials. Let's delve into the detailed applications of potassium fluotitanate as a grain refiner in industrial settings.

1、Metal Casting and Alloy Production:

Potassium fluotitanate is extensively utilized in the metal casting industry to refine the grain structure of metals and alloys. The addition of this compound during the casting process promotes uniform grain distribution, resulting in improved mechanical properties such as strength and ductility.

2、Aluminum Alloys:

In the production of aluminum alloys, potassium fluotitanate acts as an effective grain refiner. By adding precise amounts of K2TiF6 to the molten aluminum, the formation of fine and evenly distributed grains is facilitated. This refinement enhances the strength and casting characteristics of aluminum alloys, making them suitable for various applications in automotive and aerospace industries.

3、Magnesium Alloys:

Similar to its role in aluminum alloys, potassium fluotitanate finds application in refining the grain structure of magnesium alloys. This contributes to increased corrosion resistance and mechanical strength, making magnesium alloys more durable and suitable for applications in lightweight structures and electronic devices.

4、Titanium Alloys:

Potassium fluotitanate is also employed in the production of titanium alloys. The addition of this compound assists in controlling the grain size of titanium, resulting in alloys with improved strength, fatigue resistance, and overall performance. This is particularly crucial in aerospace and medical applications where titanium alloys are extensively used.

5、Process Overview:

The application process involves adding a precise amount of potassium fluotitanate to the molten metal or alloy during the casting or alloying process. The compound acts as a nucleating agent, promoting the formation of fine grains. Careful control of the addition rate and temperature is essential to achieve the desired grain refinement effects.

6、Advantages of Using Potassium Fluotitanate:

● Improved Mechanical Properties: The refined grain structure enhances the mechanical strength, toughness, and fatigue resistance of the metal or alloy.

● Reduced Porosity: Grain refinement helps minimize the formation of porosity in the cast metal, leading to higher quality products.

● l Enhanced Casting Characteristics: Potassium fluotitanate contributes to better fluidity and mold filling during the casting process, resulting in improved casting characteristics.

Potassium fluotitanate stands as a valuable tool in the industrial realm, particularly in the production of metal alloys. Its role as a grain refiner contributes to the enhancement of mechanical properties, making materials more reliable and suitable for diverse applications across various industries. Understanding the nuances of its application is essential for optimizing the benefits it offers in the complex landscape of industrial processes.

- Fluoride Salt

- Ammonium Fluoride

- Sodium Fluoride

- Potassium Fluoride

- Sodium Hydrogenfluoride

- Potassium Bifluoride

- Magnesium Fluoride

- Aluminium Fluoride

- Barium Fluoride

- Lithium Fluoride

- Strontium Fluoride

- Nickel Fluoride

- Zinc Fluoride