Potassium Aluminum Fluoride in Abrasives: Enhancing Precision and Performance in Modern Manufacturing

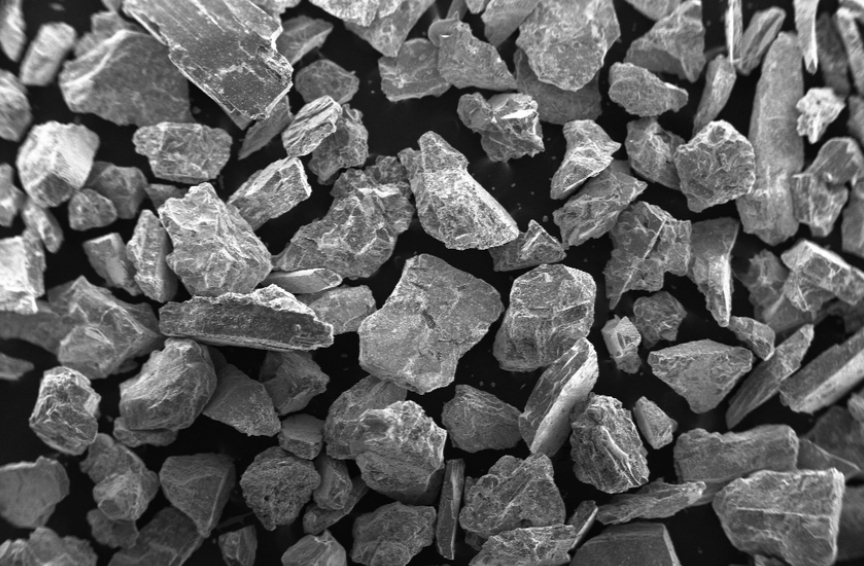

Potassium aluminum fluoride, commonly known as KAlF₄, is a versatile compound extensively used in various industries, with one of its significant applications being in the abrasive industry. This compound is valued for its ability to enhance the performance and properties of abrasive materials.

Chemical Properties

Potassium aluminum fluoride is a salt composed of potassium, aluminum, and fluorine. Its unique chemical composition provides it with desirable characteristics that make it suitable for applications in the abrasive industry.

Applications in Abrasive Industry

1、Fluxing Agent:

One primary application of potassium aluminum fluoride in the abrasive industry is as a fluxing agent. In abrasive manufacturing, it acts as a flux, lowering the melting point of raw materials. This facilitates the fusion of abrasive particles, bonding them together during the production of grinding wheels, sandpaper, and other abrasive tools.

2、Hardening Agent:

Potassium aluminum fluoride is also employed as a hardening agent in abrasive formulations. Its inclusion contributes to the hardness and wear resistance of abrasive materials, ensuring they maintain their integrity and effectiveness during grinding and shaping processes.

3、Thermal Stability:

The compound enhances the thermal stability of abrasives, allowing them to withstand high temperatures generated during grinding operations. This property is crucial for maintaining the structural integrity of abrasive tools and ensuring consistent performance in various industrial applications.

4、Abrasive Properties:

Due to its abrasive nature, potassium aluminum fluoride enhances the cutting and grinding action of abrasive materials. It improves the efficiency of material removal during grinding processes, resulting in precise shaping and finishing of workpieces.

Production Process

The production of abrasive materials incorporating potassium aluminum fluoride involves carefully controlled processes. Raw materials, including abrasive particles and bonding agents, are mixed with potassium aluminum fluoride. The mixture is then subjected to controlled heating, where the compound acts as a flux, facilitating the fusion of components. This process ensures the formation of a cohesive and durable abrasive structure.

In conclusion, potassium aluminum fluoride's application in the abrasive industry is multifaceted. As a fluxing and hardening agent, it contributes to the formation of high-quality abrasive tools with enhanced thermal stability. Its role in improving the efficiency of material removal during grinding processes highlights its significance in achieving precision and quality in various industrial applications. Understanding the science behind potassium aluminum fluoride's applications in the abrasive industry underscores its importance in shaping the tools that drive modern manufacturing and construction processes.

- Fluoride Salt

- Ammonium Fluoride

- Sodium Fluoride

- Potassium Fluoride

- Sodium Hydrogenfluoride

- Potassium Bifluoride

- Magnesium Fluoride

- Aluminium Fluoride

- Barium Fluoride

- Lithium Fluoride

- Strontium Fluoride

- Nickel Fluoride

- Zinc Fluoride