Fluotitanic Acid in Metal Passivation: A Solution for Corrosion Resistance in Stainless Steel and Aluminum Alloys

Fluotitanic acid, a specialized chemical compound, has become an essential tool in the industrial world, particularly for enhancing the corrosion resistance of stainless steel and aluminum alloys. This article explores how fluotitanic acid is applied in metal passivation, detailing its unique properties, benefits, and industrial applications.

Understanding Metal Passivation

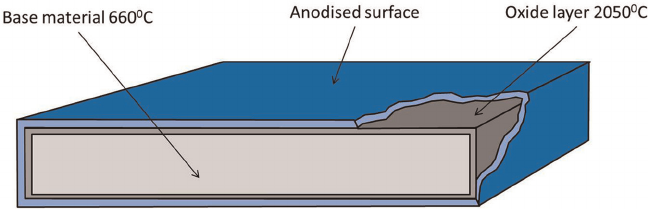

In the realm of metal manufacturing, passivation is a critical process used to increase the durability of metals exposed to corrosive environments. This process involves treating metal surfaces to develop a protective oxide layer that minimizes reactivity and rust formation. In the case of metals like stainless steel and aluminum alloys, passivation is particularly valuable, given their widespread use in industries exposed to moisture, salts, and harsh chemicals.

Stainless steel’s natural corrosion resistance stems from a thin chromium oxide layer that passivation enhances, while aluminum alloys benefit from a similar, though thinner, oxide layer. Fluotitanic acid plays a central role in creating a uniform, stable surface layer on these metals, enhancing their resistance to corrosion.

The Role of Fluotitanic Acid in Passivation

Fluotitanic acid, with the formula H2TiF6, is known for its strong acid properties and excellent complexing capabilities. When applied to metals, it cleans and prepares surfaces by dissolving contaminants and oxides, allowing the metal to achieve a cleaner, more consistent surface.

In passivation, fluotitanic acid promotes the formation of a robust and dense oxide layer. This oxide layer acts as a passive barrier against corrosive elements, making fluotitanic acid particularly suitable for critical applications in industries such as construction, transportation, and aerospace.

How Fluotitanic Acid Works on Stainless Steel

In stainless steel passivation, fluotitanic acid enhances the natural chromium oxide layer, improving the metal’s resistance to corrosion. Here’s how it works:

1、Surface Preparation: When fluotitanic acid is applied, it dissolves traces of iron and other impurities left from manufacturing. This creates a clean surface essential for effective passivation.

2、Oxide Layer Formation: The acid promotes a uniform chromium oxide layer on the steel’s surface. This is essential because an uneven or thin layer can leave the steel vulnerable to localized corrosion.

3、Reduced Sensitivity to Corrosive Environments: With a dense oxide layer formed through fluotitanic acid treatment, stainless steel components can resist harsher environments. This process helps prevent pitting and crevice corrosion, extending the metal’s lifespan.

Fluotitanic acid’s unique chemical structure allows it to dissolve unwanted surface contaminants effectively without excessive etching, preserving the metal's smoothness.

Applications for Aluminum Alloys

For aluminum alloys, fluotitanic acid provides significant passivation benefits, which are crucial in industries where aluminum is valued for its lightweight and strength. Aluminum forms an oxide layer naturally, but fluotitanic acid enhances this layer to better protect against corrosion.

1、Strengthening the Oxide Layer: The treatment with fluotitanic acid results in an even and continuous oxide film on the aluminum surface, which is denser and more adherent than the naturally occurring layer.

2、Enhanced Durability: With the improved oxide layer, aluminum components can withstand exposure to moisture, chemicals, and other environmental factors that typically cause aluminum to degrade.

3、Reduced Maintenance: This treatment results in a longer-lasting protective layer, which means that products made from aluminum alloys require less maintenance and exhibit extended durability.

This passivation method is particularly beneficial in the automotive, aerospace, and electronics industries, where aluminum alloy components are exposed to various stress factors and corrosive environments.

Industrial Benefits of Using Fluotitanic Acid

Using fluotitanic acid in passivation offers numerous benefits, including:

● Higher Corrosion Resistance: Treated metals show increased resistance to corrosion and oxidation, making them suitable for marine and industrial applications.

● Improved Surface Uniformity: Fluotitanic acid treatment results in a smooth, uniform oxide layer that adds to the aesthetic and functional value of the metal.

● Cost-Effectiveness: The efficiency of fluotitanic acid in forming a stable layer can reduce the need for frequent retreatments, lowering maintenance costs.

● Environmental Compatibility: Fluotitanic acid is less aggressive than some other acids used in passivation, making it a preferred option for manufacturers focused on reducing environmental impact.

Industries benefit from lower long-term costs, increased part durability, and fewer disruptions due to corrosion-related repairs.

Common Applications of Fluotitanic Acid in Industry

Due to its high efficiency and favorable properties, fluotitanic acid finds applications in various industries where metals face high corrosion risks. Some of the most notable applications include:

● Aerospace: For airframe structures, landing gear, and other components that encounter stress and harsh environments.

● Automotive: Used in the passivation of exhaust systems, chassis, and other components exposed to road salts and moisture.

● Construction: Applied to structural components such as beams, fasteners, and connectors that require long-term corrosion resistance.

● Electronics: In electronic enclosures and frames, particularly those exposed to humidity and varying temperatures.

These applications highlight the broad utility of fluotitanic acid across sectors, where corrosion resistance is crucial for both safety and performance.

Fluotitanic acid’s role in the passivation of stainless steel and aluminum alloys is rooted in its ability to create a stable, protective oxide layer, making it invaluable in industries requiring durable, corrosion-resistant metals. As industries evolve and place greater demands on materials, fluotitanic acid is likely to remain a preferred choice for passivation, ensuring that essential components stand the test of time.

The versatility and effectiveness of fluotitanic acid make it a valuable tool for manufacturers, engineers, and designers across industries. Whether used in automotive parts, aerospace frames, or construction beams, the advantages of fluotitanic acid in passivation are clear. By creating a resilient and uniform oxide layer, it not only extends the life of metal components but also contributes to safer, more reliable products.