How and Why Potassium Fluoride (KF) is Used in Welding and Brazing Processes

In the world of metalworking, processes like welding and brazing are essential for joining metals, creating strong and durable connections that can withstand wear and tear. However, successful welding and brazing depend on various supporting materials, known as fluxes, which facilitate the bonding process. Among these, potassium fluoride (KF) stands out as a valuable component for improving weld and brazed joint quality. This article explores the principles behind KF’s role in welding and brazing and why it’s so beneficial for achieving clean, high-quality bonds.

1. The Science Behind KF’s Role in Welding and Brazing

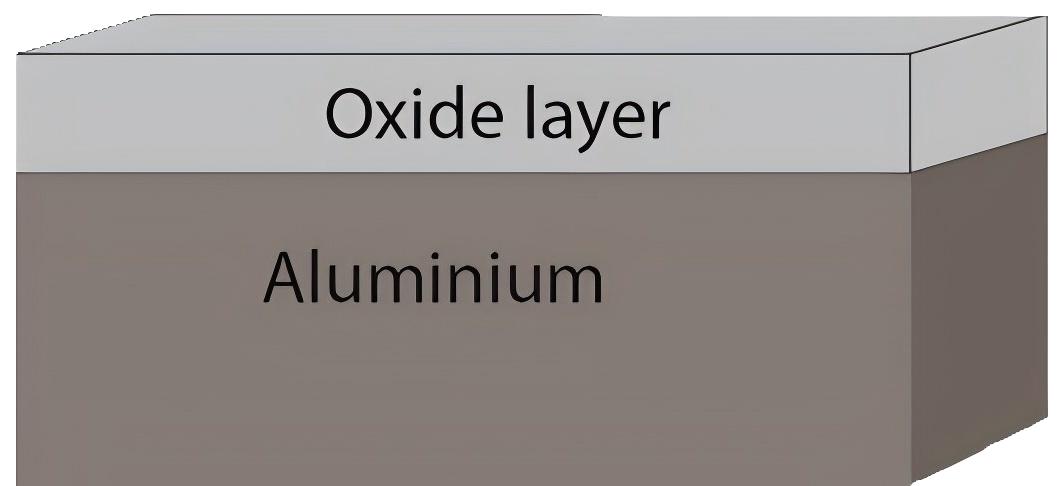

To understand KF's importance, it’s essential to grasp the challenges that arise when bonding metals at high temperatures. When metals are heated, they tend to react with oxygen in the air, forming oxides on their surfaces. This oxidation process can create a barrier between the metal surfaces, preventing a clean, strong bond from forming. Potassium fluoride helps overcome this obstacle by chemically interacting with these oxides and removing them, which prepares the metal surfaces for effective joining.

● Oxide Removal: Potassium fluoride is highly effective in removing oxides such as aluminum oxide (Al₂O₃) and magnesium oxide (MgO), which form on metals like aluminum and stainless steel. KF’s chemical structure enables it to break down these stable oxides, leaving behind clean, reactive metal surfaces.

● Enhanced Metal Wetting: KF not only removes oxides but also enhances the wetting properties of molten metals. Wetting is essential for achieving a consistent and durable joint, as it allows the filler material (in brazing) or base metals (in welding) to spread evenly over the bonding area.

● Thermal Stability: Unlike some fluxes that may degrade or evaporate under high heat, potassium fluoride remains stable at high temperatures, making it suitable for various welding and brazing processes that require consistent flux performance across a wide range of temperatures.

2、Chemical Reactions of KF with Metal Oxides

The chemistry of potassium fluoride with metal oxides is critical to its effectiveness as a flux. When KF is exposed to the high temperatures present during welding or brazing, it releases fluoride ions. These ions actively interact with the oxide layers on metal surfaces, converting them into compounds that dissolve or evaporate, effectively "cleaning" the surface.

● Reaction with Aluminum Oxide (Al₂O₃): Aluminum, one of the most commonly welded and brazed metals, forms a tough oxide layer almost immediately when exposed to air. This oxide layer is highly resistant to breakdown, which can complicate the bonding process. Potassium fluoride reacts with aluminum oxide to form potassium aluminate, which melts or dissipates, leaving a clean aluminum surface ready for bonding.

● Reaction with Magnesium Oxide (MgO): Magnesium is often used in lightweight alloys but is also prone to oxidation. Potassium fluoride assists in breaking down magnesium oxide layers, allowing for improved bonding in magnesium-containing alloys.

3、Advantages of Using Potassium Fluoride in Welding and Brazing

● Stronger Bonds: By effectively removing metal oxides, KF allows for a purer, more secure bond between metal surfaces. This leads to joints with improved structural integrity, making them less likely to fail under stress.

● Improved Corrosion Resistance: Oxides and impurities within a joint can compromise its corrosion resistance. KF’s ability to eliminate these impurities ensures a cleaner, more corrosion-resistant bond, extending the life of the welded or brazed component.

● Enhanced Bonding of Challenging Metals: Metals like aluminum, stainless steel, and certain exotic alloys are known for their tendency to form oxide layers that impede bonding. Potassium fluoride is particularly effective with these challenging metals, allowing for more successful bonding without the need for additional complex treatments.

● Higher Quality for Precision Applications: KF’s effectiveness in achieving a clean bond is especially valuable in industries where precision and durability are essential, such as aerospace, automotive, and electronics. By ensuring high-quality, oxide-free bonding, potassium fluoride enables the production of reliable, durable components.

4、Applications of Potassium Fluoride in Specific Welding and Brazing Processes

● Aluminum Brazing in the Automotive and Aerospace Industries: Potassium fluoride is a key component in fluxes used to braze aluminum parts in automobiles and aircraft. Since aluminum easily oxidizes, KF-based fluxes are critical for removing oxide layers and ensuring clean, strong joints that can withstand mechanical and thermal stresses.

● Stainless Steel Welding for Construction and Manufacturing: Stainless steel, commonly used in construction and manufacturing, also benefits from KF-based fluxes. Stainless steel’s chromium content makes it prone to forming stable oxides that are hard to break down, but KF effectively handles this issue, enabling smooth, clean welds.

● Precision Electronics Assembly: In electronics, where small, delicate joints must withstand environmental stress, brazing is often preferred over welding. Potassium fluoride-based fluxes enable precise bonding without compromising the electrical properties or durability of the connections, making it ideal for assembling components in electronics.

5、The Future of Potassium Fluoride in Welding and Brazing

As technology advances and industries demand stronger, lighter, and more corrosion-resistant materials, the role of potassium fluoride in welding and brazing is likely to expand. Researchers are exploring the potential of KF-based fluxes with additives that enhance its oxide-removal properties and thermal stability. Additionally, eco-friendly alternatives to current fluoride-based fluxes are being studied, which could reduce environmental impact while maintaining similar performance in welding and brazing applications.

Potassium fluoride’s ability to remove oxides and prepare metal surfaces for bonding makes it an essential flux in welding and brazing. Its effectiveness across various metals and processes, combined with its stability at high temperatures, ensures high-quality joints with enhanced corrosion resistance and structural integrity. As industries continue to push the boundaries of material science, KF’s role in creating reliable, durable metal bonds will remain invaluable. For engineers, manufacturers, and scientists, potassium fluoride offers a reliable means of achieving precision and durability in welded and brazed assemblies.