Why Fluozirconic Acid is Used as a Functional Coating Additive in Paint Manufacturing

In modern paint manufacturing, functional additives play a critical role in enhancing the performance of coatings. Among these, fluozirconic acid (H2ZrF6) stands out for its unique chemical and physical properties that make it indispensable in specific industrial applications. This article delves into the reasons why fluozirconic acid is widely used as a functional coating additive, its mechanisms of action, and its benefits to the paint industry.

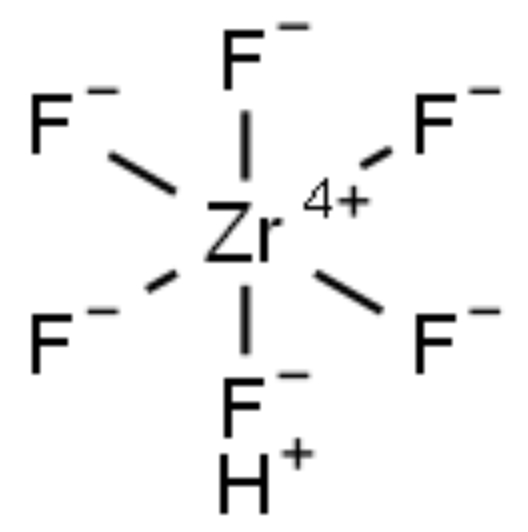

Understanding Fluozirconic Acid

Fluozirconic acid is an inorganic compound that contains zirconium and fluoride ions. It is a water-soluble acid known for its ability to interact chemically with various substrates, particularly metals. This interaction forms durable and protective layers that enhance the performance of coatings applied over them.

Key Properties of Fluozirconic Acid:

1、Reactivity with Metals: Its ability to chemically bond with metal surfaces makes it ideal for applications requiring strong adhesion and corrosion resistance.

2、Versatility: Fluozirconic acid is effective across a range of metals, including steel, aluminum, and their alloys.

3、Environmental Compliance: As a non-chromium-based compound, it offers an eco-friendly alternative to traditional pretreatment chemicals.

4、Thermal Stability: The compound remains effective under high-temperature conditions, making it suitable for industrial environments.

Why is Fluozirconic Acid Used in Paint Manufacturing?

The primary reasons for incorporating fluozirconic acid into the paint manufacturing process lie in its ability to improve adhesion, enhance corrosion resistance, and optimize surface preparation. These benefits address critical challenges faced by manufacturers and end-users alike.

1、Superior Surface Preparation

Proper surface preparation is a prerequisite for any successful coating application. Fluozirconic acid ensures that metal substrates are clean and chemically active, which enhances the performance of subsequent coatings.

● Removal of Impurities: The acid dissolves surface contaminants, such as oxides, grease, and mill scale, leaving behind a clean surface that facilitates coating adhesion.

● Activation of Metal Surfaces: By reacting with the substrate, fluozirconic acid creates a chemically reactive surface that binds strongly to primers and paints.

● Prevention of Flash Rusting: Its use minimizes the likelihood of flash rusting during the pretreatment process.

2、Formation of a Protective Conversion Layer

One of the standout features of fluozirconic acid is its ability to form a zirconium-based conversion coating. This layer acts as a bridge between the metal substrate and the paint, improving both adhesion and protection.

● Chemical Bonding: The zirconium conversion layer chemically bonds to the metal, providing a stable foundation for coatings.

● Corrosion Resistance:The layer acts as a barrier, reducing the permeability of corrosive agents like water, oxygen, and salts.

● Enhanced Longevity: Coatings applied over this conversion layer exhibit prolonged life spans, reducing maintenance requirements.

3、Enhanced Paint Adhesion

Strong adhesion between the coating and the substrate is essential for durability. Fluozirconic acid promotes this adhesion through several mechanisms:

● Increased Surface Energy: The acid-treated surface becomes more hydrophilic, allowing paints and primers to spread uniformly and adhere better.

● Microscopic Roughening: The chemical interaction subtly etches the metal surface, creating micro-level roughness that enhances mechanical interlocking of the coating.

● Compatibility with Modern Paints: It ensures adhesion with advanced waterborne and solvent-based coating systems.

4、Improved Durability of Coatings

Fluozirconic acid-treated surfaces result in coatings that are more durable and resistant to environmental wear.

● Abrasion Resistance: By forming a strong bond between the coating and the substrate, the additive reduces the likelihood of chipping and peeling.

● Weathering Performance: Coatings on fluozirconic acid-treated surfaces better withstand UV exposure, temperature fluctuations, and moisture.

● Resistance to Chemical Exposure: Treated surfaces show improved resistance to chemicals, including acids and alkalis.

Industries Benefiting from Fluozirconic Acid Additives

Automotive Coatings

In the automotive industry, where durability and appearance are paramount, fluozirconic acid is used to prepare metal surfaces before applying primers and topcoats. Its ability to enhance adhesion and prevent corrosion ensures that vehicles maintain their finish for years.

● Lightweight Materials: Fluozirconic acid is particularly effective on aluminum, a key material in lightweight automotive designs.

Industrial Machinery

For machinery exposed to harsh environments, such as factories or construction sites, fluozirconic acid-treated coatings provide long-lasting protection against wear and corrosion.

● High-Impact Resistance: Coatings on treated surfaces better withstand mechanical stresses from heavy equipment use.

Marine Coatings

Marine environments are notorious for their corrosive properties. Fluozirconic acid improves the saltwater resistance of coatings applied to ships, oil rigs, and other marine equipment.

● Anti-Fouling Properties: Treated surfaces support coatings that resist biological fouling, such as barnacle growth.

Architectural Coatings

For buildings exposed to extreme weather, fluozirconic acid improves the longevity and appearance of protective coatings on metal structures.

How Fluozirconic Acid Works in Paint Manufacturing

The efficacy of fluozirconic acid as a functional coating additive lies in its chemical properties and interactions during the coating process.

Step 1: Surface Treatment

Fluozirconic acid is applied to the metal surface during the pretreatment stage. The acid reacts with the metal’s oxides, cleaning the surface and forming a reactive layer.

● Neutralization of Alkaline Contaminants: It neutralizes any residual alkalinity, ensuring uniform surface reactivity.

Step 2: Conversion Coating Formation

As the acid reacts, it forms a zirconium-based conversion layer that bonds chemically to the substrate. This layer enhances adhesion and provides a base for the primer.

● Thickness Control: Manufacturers can adjust the process parameters to create a layer of optimal thickness for specific applications.

Step 3: Paint Application

Primers and paints are then applied over the treated surface. The conversion layer ensures uniform paint adhesion and minimizes defects such as blistering or peeling.

● Electrostatic Compatibility: The treated surfaces improve the efficiency of electrostatic paint applications.

Advantages of Using Fluozirconic Acid

1、Environmental Compliance

Fluozirconic acid serves as a safer alternative to traditional chromate-based pretreatments, which are toxic and subject to strict regulations.

● Regulatory Approval: It complies with stringent environmental standards worldwide.

2、Cost-Effectiveness

By improving adhesion and durability, fluozirconic acid reduces the need for frequent repainting or maintenance, lowering long-term costs.

● Energy Efficiency: It allows for lower curing temperatures in some paint systems, saving energy during manufacturing.

3、Compatibility with Modern Coatings

It works well with advanced coating systems, including powder coatings and waterborne paints, making it suitable for modern manufacturing needs.

● Flexibility in Application: The additive adapts to automated processes, increasing manufacturing efficiency.

Fluozirconic acid has emerged as a vital additive in the paint manufacturing process, offering unmatched benefits in adhesion, corrosion resistance, and environmental compliance. Its ability to prepare surfaces effectively and enhance the durability of coatings makes it a preferred choice for industries ranging from automotive to marine. As manufacturers continue to seek eco-friendly and high-performance solutions, fluozirconic acid’s role in the coatings industry is poised to grow further, ensuring its place as a cornerstone of modern paint technology. By integrating fluozirconic acid into manufacturing workflows, industries can achieve higher efficiency, durability, and environmental stewardship in their coating applications.