How Can Hydrofluoric Acid be used in Stainless Steel Industry

Hydrofluoric acid (HF) is a highly corrosive and toxic acid, which has unique properties making it essential in several industrial applications. One such application is in the stainless steel industry, where HF plays a crucial role in processes like cleaning, pickling, and surface treatment. This article explores the necessity of hydrofluoric acid in the stainless steel industry, explaining its uses, benefits, and the precautions required to handle this dangerous chemical safely.

Importance of Hydrofluoric Acid in Stainless Steel Processing

Stainless steel, an alloy of iron, chromium, nickel, and other metals, is renowned for its resistance to corrosion and high strength. However, during manufacturing and processing, stainless steel surfaces can develop oxides, scale, and other contaminants that must be removed to maintain its desirable properties. Hydrofluoric acid is used in the following key processes within the stainless steel industry:

1、Pickling:

One of the primary uses of hydrofluoric acid in the stainless steel industry is in acid pickling. Acid pickling is a process used to remove oxide scales, rust, and other impurities from the surface of stainless steel. These contaminants form during hot working processes such as rolling, forging, and welding. The oxide layers are typically very tough and adhere strongly to the metal surface.

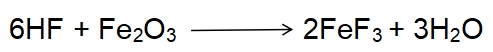

Hydrofluoric acid is used in combination with nitric acid (HNO3) in what is known as a "mixed acid" bath. This mixture is effective in removing the oxide scales and cleaning the metal surface. The reaction between HF and the oxide scales can be summarized as follows:

This reaction shows how HF dissolves iron oxides, converting them into soluble iron fluoride (FeF3) and water, thereby cleaning the metal surface.

2、Weld Cleaning:

During the welding of stainless steel, high temperatures cause the formation of a thick oxide layer along the weld seam. This oxide layer, often called "heat tint," is not only unsightly but can also affect the corrosion resistance of the welded area. Hydrofluoric acid is used to remove these oxides effectively.

After welding, the welded parts are treated with a pickling paste or gel containing hydrofluoric acid. This treatment removes the heat tint and restores the original corrosion resistance and appearance of the stainless steel. The application of HF for weld cleaning ensures that the welds are smooth and clean, which is critical for maintaining the structural integrity and aesthetic quality of the final product.

3、Surface Treatment and Passivation

Passivation is a chemical treatment process that enhances the corrosion resistance of stainless steel by forming a thin, protective oxide layer on its surface. Hydrofluoric acid is used in conjunction with nitric acid to clean the stainless steel surface before passivation. This pre-treatment step ensures that any contaminants, such as oils, grease, and oxide scales, are removed, allowing for the formation of a uniform and stable passive layer.

The typical steps in the passivation process involving HF include:

● Cleaning the stainless steel surface with a mixture of HF and nitric acid to remove contaminants and oxides.

● Rinsing thoroughly with water to remove all traces of acids.

● Treating the clean surface with a passivating solution, typically containing nitric acid, to form the protective oxide layer.

4、Oxide Scale Removal

During the manufacturing and heat treatment of stainless steel, oxide scales can form on the metal surface. These scales are often very tough and cannot be easily removed by mechanical means. Hydrofluoric acid is effective in breaking down these scales, facilitating their removal.

The effectiveness of HF in oxide scale removal can be attributed to its ability to dissolve both iron oxides and chromium oxides, which are common components of the scale on stainless steel. This capability makes HF an indispensable tool in ensuring that the final product has a clean and smooth surface, ready for further processing or finishing.

In conclusion, hydrofluoric acid (HF) emerges as a cornerstone in the stainless steel industry, vital for achieving pristine surfaces and maintaining the integrity of stainless steel products. From its role in acid pickling to weld cleaning, surface treatment, and oxide scale removal, HF's unique properties and versatility make it indispensable in various manufacturing processes. However, it's imperative to underscore the inherent hazards associated with HF and emphasize the importance of stringent safety protocols and proper handling practices. By understanding the necessity of hydrofluoric acid and implementing precautionary measures, the stainless steel industry can harness its benefits effectively while ensuring the safety of workers and the environment.