Potassium Fluoroborate as A Superior Grinding Material

Potassium fluoroborate, also known as KBF4, is a unique compound that has various industrial applications. One of its most remarkable characteristics is the ability to function as a grinding material. In this article, we will discuss the chemistry and properties of KBF4, how it works as a grinding material, and compare its advantages to other abrasive substances. We will also highlight the specific areas of application for this outstanding material.

Chemistry of Potassium Fluoroborate:

Potassium fluoroborate is an ionic compound that contains the ions K+ and BF4-. It is synthesized by the reaction between potassium fluoride and boron trifluoride. The compound is soluble in water, alcohol, and other polar solvents. KBF4 is chemically stable and can withstand high temperatures without decomposing, making it an ideal material for various industrial applications.

How KBF4 functions as a grinding material:

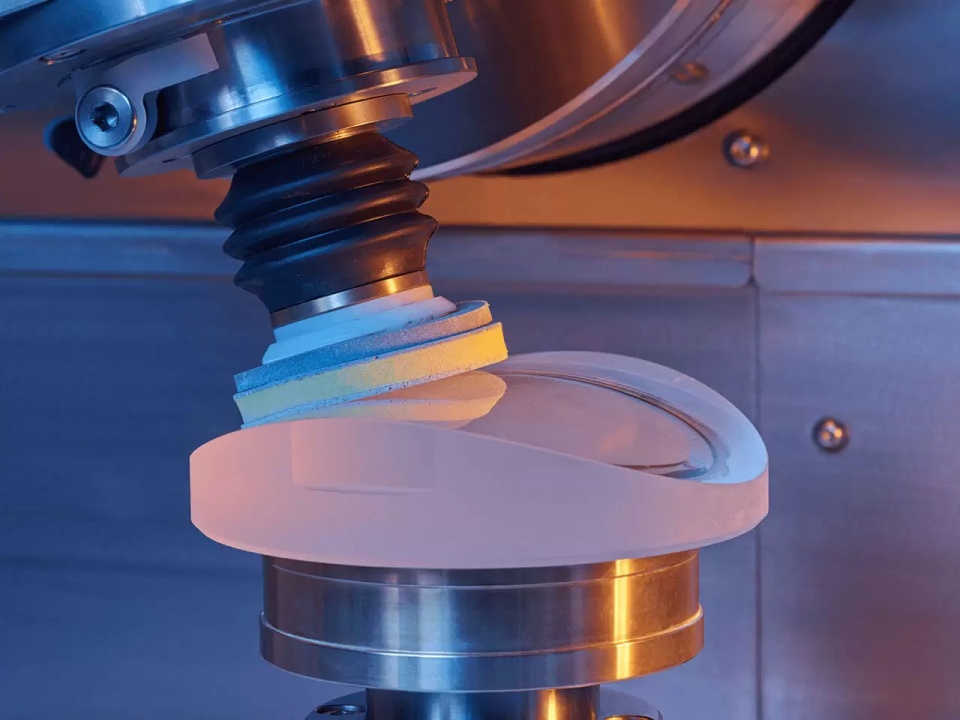

KBF4 is a soft, white powder that has a distinct crystalline structure. This crystalline structure allows KBF4 particles to interact with other materials in a unique way. When KBF4 particles come into contact with another material, their sharp, crystalline edges scrape and penetrate the surface of the material. This scraping action, combined with the hardness of the KBF4 particles, grinds away the surface layer, exposing the unspoiled layer beneath it, effectively polishing or sanding the material.

Advantages of KBF4 as a grinding material:

There are several advantages to using KBF4 as a grinding material over other substances. First, KBF4 particles are very sharp and hard, allowing them to cut through materials quickly and efficiently. This makes KBF4 an excellent option for materials that are notoriously difficult to grind or polish, such as glass and ceramics. Second, KBF4 particles leave a smooth surface finish, without any micro-scratches or residue. This is perfect for applications that require a high level of precision and surface quality. Finally, unlike other abrasive materials, KBF4 particles do not react chemically with many materials, such as metals, plastics and rubbers. This makes KBF4 a safer and more environmentally friendly option that can be used across a wide range of industries.

Areas of application for KBF4:

KBF4 has a wide range of applications, including the polishing of optical lenses and mirrors, the grinding and polishing of semiconductors, the processing of synthetic diamonds and abrasives, and the manufacture of soldering fluxes and welding rods. It is also used as an active ingredient in fluxes for brazing and welding, as a corrosion inhibitor, and in the production of specialty chemicals and pharmaceuticals. Its versatility makes it a highly valued compound across various industrial sectors.

Potassium fluoroborate possesses exceptional properties that make it an effective and efficient grinding material. Its unique chemistry and crystalline structure give it advantages over other abrasive substances in precision grinding, polishing, and sanding of fragile and hard-to-grind materials. Its versatility also makes it a highly valued compound across various industrial sectors, including electronics, metallurgy, and optics. KBF4's advent marks a significant milestone in the development of superior grinding materials, leading to various industrial breakthroughs and technological advancements.

- Fluoride Salt

- Ammonium Fluoride

- Sodium Fluoride

- Potassium Fluoride

- Sodium Hydrogenfluoride

- Potassium Bifluoride

- Magnesium Fluoride

- Aluminium Fluoride

- Barium Fluoride

- Lithium Fluoride

- Strontium Fluoride

- Nickel Fluoride

- Zinc Fluoride