The Significance of Fluotitanic Acid as a Pretreatment Agent

Fluotitanic acid, a compound composed of titanium and fluorine atoms, stands as a pivotal component in various industrial applications, particularly in surface treatments and material processing. Its chemical properties and reactivity make it a sought-after ingredient in pretreatment agents, contributing significantly to surface modification and substrate preparation. Let's explore its chemical characteristics, reactions as a pretreatment agent, industrial applications, and advantages over alternative treatments.

Fluotitanic acid exhibits strong acidic properties owing to the presence of fluorine atoms, making it highly reactive with metal surfaces. Its ability to interact with oxides, oils, and other contaminants allows for effective surface cleaning and activation, essential for subsequent processing steps.

When used as a pretreatment agent, fluotitanic acid undergoes chemical reactions with surface contaminants and oxides on metal substrates. It reacts with metal oxides, forming soluble complexes that can be easily removed from the surface, thereby cleaning and activating the substrate. Additionally, it can react with organic contaminants, such as oils and greases, breaking them down into smaller, more manageable compounds.

Specific Industrial Applications:

Fluotitanic acid-based pretreatment agents find extensive applications across various area due to their versatile capabilities:

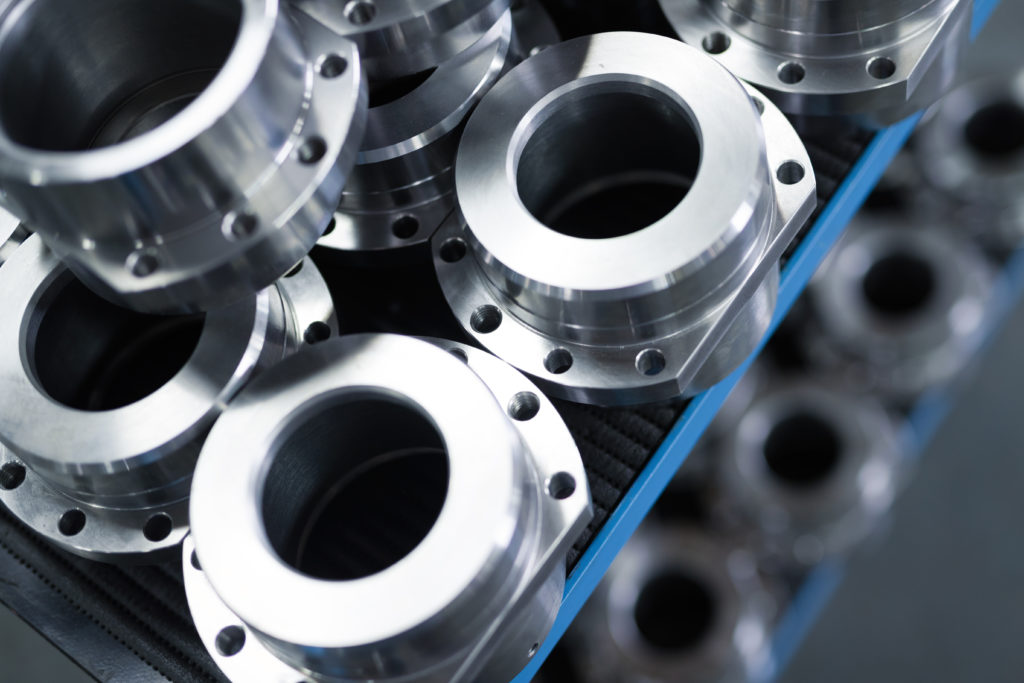

1、Metal Surface Cleaning: Fluotitanic acid is widely employed for the cleaning of metal surfaces prior to further processing. It effectively removes various contaminants such as oils, greases, rust, and other impurities that may be present on the surface. This thorough cleaning is essential to ensure the removal of any substances that could hinder subsequent treatments or affect the quality of the final product.

2、Surface Activation: One of the key functions of fluotitanic acid in pretreatment processes is surface activation. When applied to metal surfaces, fluotitanic acid reacts with oxides present on the surface, effectively etching and creating a chemically active substrate. This activated surface enhances the adhesion of subsequent coatings, platings, or adhesives, facilitating better bonding and improved performance of the treated metal components.

3、Corrosion Protection: Pretreatment with fluotitanic acid contributes to the formation of a protective layer on metal surfaces, thereby enhancing their resistance to corrosion. By removing surface contaminants and activating the substrate, fluotitanic acid helps in the formation of a corrosion-resistant barrier, which is particularly crucial for metal components exposed to harsh environmental conditions or corrosive substances.

4、Improving Paint Adhesion: Fluotitanic acid-treated metal surfaces exhibit improved adhesion properties, making them suitable for painting applications. The removal of contaminants and activation of the surface create a clean and roughened surface, which promotes better bonding between the paint and the metal substrate. This results in enhanced durability and longevity of painted surfaces, reducing the likelihood of paint delamination or corrosion.

5、Preparation for Further Processing: Fluotitanic acid pretreatment prepares metal surfaces for subsequent manufacturing processes such as welding, brazing, or adhesive bonding. The clean, activated surface ensures optimal performance and integrity of the assembled components, minimizing defects and enhancing the overall quality of the finished product.

In summary, the application of fluotitanic acid as a pretreatment agent is essential for ensuring the cleanliness, activation, and protection of metal surfaces in various industrial processes. Its role in cleaning, activating, and protecting metal surfaces significantly contributes to the quality, durability, and performance of finished products across industries ranging from automotive and aerospace to electronics and construction.