How Zinc Fluorosilicate Works to Protect Steel and Concrete Structures from Corrosion

Zinc fluorosilicate (ZnSiF6) is an inorganic compound increasingly recognized for its utility in the construction industry, particularly as a corrosion inhibitor for steel and concrete structures. This article explores the principles behind its effectiveness and the various ways it can be applied in construction, highlighting its significance in enhancing the durability of these materials.

The Chemistry of Zinc Fluorosilicate

Zinc fluorosilicate is formed through the interaction of zinc oxide (ZnO) with hydrofluoric acid (HF) in the presence of silica. The resulting compound possesses unique properties, making it a suitable choice for protecting metals and concrete from the detrimental effects of corrosion. The chemical structure allows zinc ions to bond with various substrates, facilitating a protective layer that inhibits corrosion.

The Importance of Corrosion Protection

Corrosion is a primary concern in construction, especially for steel and reinforced concrete. It can lead to structural failures, increased maintenance costs, and safety hazards. Steel structures are particularly vulnerable, as rust formation can compromise their integrity. Similarly, in concrete, the corrosion of embedded steel rebar weakens the overall structure, leading to spalling and cracking.

Mechanisms of Action

Zinc fluorosilicate functions through several mechanisms that collectively enhance the resistance of steel and concrete to corrosion:

1、Cathodic Protection: Zinc ions in the fluorosilicate compound act as a sacrificial anode. When applied to steel, these ions oxidize preferentially, protecting the underlying metal from corrosion. This cathodic protection is crucial in environments where moisture and oxygen promote rust formation.

2、Formation of Protective Films: When zinc fluorosilicate is applied, it forms a protective layer on the surface of steel and concrete. This layer acts as a barrier that limits the penetration of moisture and corrosive agents, significantly reducing the rate of corrosion. The silica component contributes to the durability of this film, ensuring it withstands environmental stressors.

3、Enhancing Concrete Properties: In concrete applications, zinc fluorosilicate not only protects embedded steel but also enhances the overall properties of the concrete. It improves resistance to chemical attacks (such as sulfates and chlorides) and increases the adhesion of coatings, making it a multifunctional additive.

Applications in Steel Structures

Zinc fluorosilicate is widely used in various steel applications:

● Protective Coatings: One of the most common applications is in protective coatings for steel. When zinc fluorosilicate is incorporated into paints, it significantly enhances their corrosion resistance. These coatings are ideal for bridges, industrial structures, and marine environments where exposure to moisture and salt is prevalent.

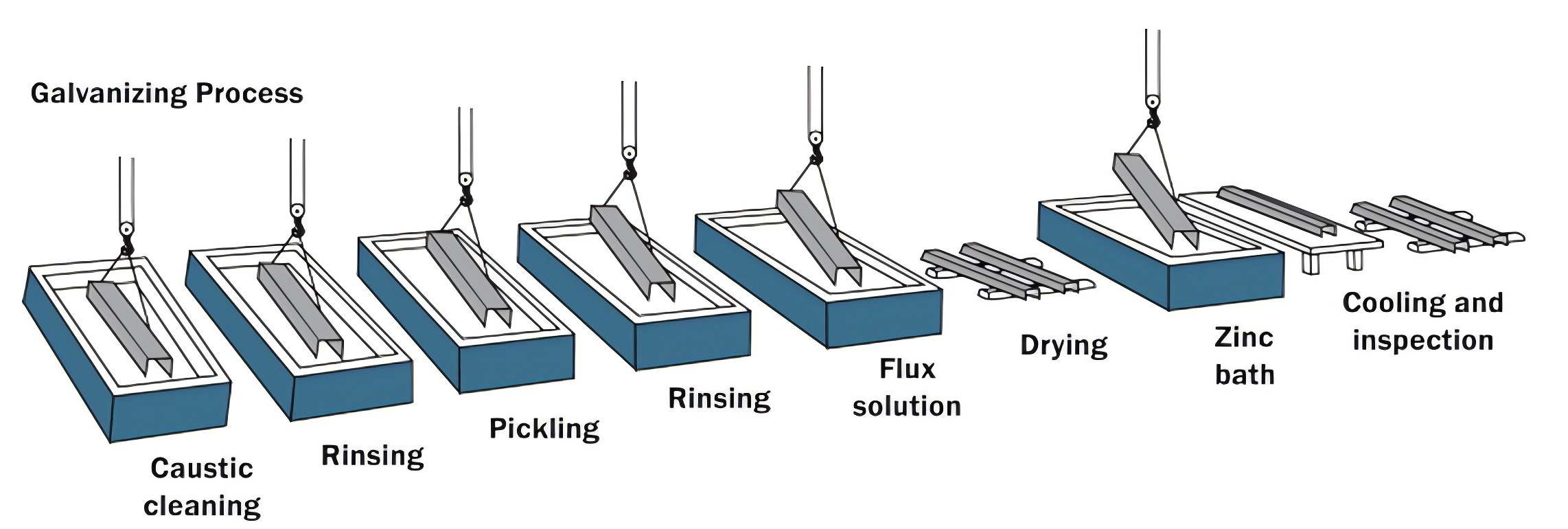

● Galvanizing Processes: The compound is also utilized in galvanizing processes, where steel is coated with a layer of zinc. This method combines zinc fluorosilicate's protective properties with the galvanic protection offered by the zinc layer, providing a robust defense against corrosion.

Applications in Concrete Structures

In concrete applications, zinc fluorosilicate serves as both an additive and a surface treatment:

● Additive in Concrete Mixes: When mixed into concrete, zinc fluorosilicate improves the material's durability and resistance to aggressive environments. It is particularly effective in precast concrete elements, where longevity and performance are critical.

● Surface Treatment: For existing concrete structures, zinc fluorosilicate can be applied as a surface treatment. This involves cleaning the concrete surface and applying a solution of zinc fluorosilicate, which penetrates the substrate and forms a protective layer against moisture and corrosive elements.

Several case studies illustrate the successful application of zinc fluorosilicate:

● Bridge Construction: A notable project involved a major highway bridge where zinc fluorosilicate-based coatings were applied to steel girders. The treatment resulted in a significant reduction in maintenance costs over the lifespan of the bridge, demonstrating the effectiveness of the protective measures.

● Industrial Facilities: In an industrial facility exposed to harsh chemical environments, the use of zinc fluorosilicate in both the structural steel and concrete foundations prevented corrosion-related issues, extending the service life of the facility and reducing downtime for repairs.

Environmental Benefits

Beyond its protective qualities, zinc fluorosilicate is also recognized for its environmental benefits. Unlike some traditional corrosion inhibitors, it is less toxic, making it a safer option for construction projects. Its effectiveness in enhancing the durability of structures contributes to sustainability by reducing the frequency of repairs and replacements, thereby minimizing waste.

Zinc fluorosilicate plays a vital role in enhancing the longevity and performance of steel and concrete structures. Through mechanisms such as cathodic protection and the formation of protective films, it effectively mitigates the risks associated with corrosion. As the construction industry continues to prioritize durability and sustainability, the applications of zinc fluorosilicate will likely expand, making it an essential component in modern construction practices.