How Potassium Tetrafluoroborate (KBF4) Powers the Electronics Industry: Key Principles and Advantages

Potassium tetrafluoroborate (KBF4) is a highly versatile compound used extensively in the electronics industry due to its unique chemical properties and interactions with other materials. Its use ranges from semiconductor doping to assisting in the manufacturing processes of various electronic components. Understanding how KBF4 operates at a molecular level and what advantages it brings to the production of electronic devices is crucial for comprehending its role in modern technology. In this article, we will dive deeper into the underlying principles and specific benefits that potassium tetrafluoroborate provides in the electronics sector.

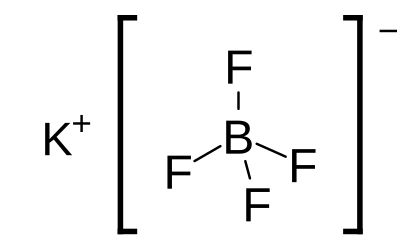

1、Chemical Structure and Properties of KBF4

Before examining how KBF4 is applied in the electronics industry, it is essential to understand its chemical structure and properties. Potassium tetrafluoroborate is composed of potassium ions (K+) and tetrafluoroborate ions (BF4-), with the BF₄⁻ ion consisting of one boron atom bonded to four fluorine atoms in a tetrahedral arrangement. This structure results in a compound that is chemically stable and highly reactive with certain metals and other substances under specific conditions.

The strong bonds between boron and fluorine give KBF4 a high thermal stability, making it resistant to decomposition at elevated temperatures. This is a critical property in the high-temperature environments encountered in semiconductor processing and other electronic manufacturing steps.

2. Role in Semiconductor Doping

One of the key applications of potassium tetrafluoroborate in electronics lies in semiconductor doping, a process that involves introducing impurities into pure semiconductor materials to alter their electrical properties. The doping process is fundamental in creating materials like p-type or n-type silicon, which are essential for manufacturing diodes, transistors, and integrated circuits.

KBF4 acts as a source of boron during p-type doping, where boron atoms are introduced into a silicon lattice. Boron, a group III element, has three valence electrons, while silicon has four. When boron is added to the silicon crystal structure, it creates "holes" or deficiencies of electrons, leading to an increase in positive charge carriers, which enhances the material's conductivity.

The advantage of using KBF4 in this process is its controlled release of boron. During the thermal diffusion process, KBF4 decomposes in a way that allows precise amounts of boron to be introduced into the silicon lattice, ensuring uniformity across the wafer. This precision is crucial for maintaining the performance and reliability of semiconductor devices.

Additionally, KBF4’s high thermal stability allows it to withstand the elevated temperatures required in the doping process without decomposing prematurely or causing unwanted reactions with other materials. This ensures the integrity of the doped semiconductor material and contributes to the production of high-quality electronic components.

3、Etching Capabilities

Another significant principle behind the application of KBF4 in electronics is its role in the etching processes. In semiconductor manufacturing, etching is used to remove layers of material from a wafer to create the desired patterns and structures necessary for electronic circuits.

KBF4, when combined with other chemicals, creates an etching solution that selectively removes material from certain areas of the wafer while leaving other regions untouched. This selective etching is important for developing intricate microstructures in integrated circuits, where precision at the nanoscale is required.

What sets KBF4 apart in etching processes is its ability to react efficiently with oxides and other compounds on the wafer's surface. It aids in dissolving these unwanted layers without damaging the underlying semiconductor, thus allowing for clean, precise patterning. The high reactivity of KBF4 with oxides makes it especially effective in cleaning up surfaces during fabrication, ensuring that the resulting device has the desired properties and operates reliably.

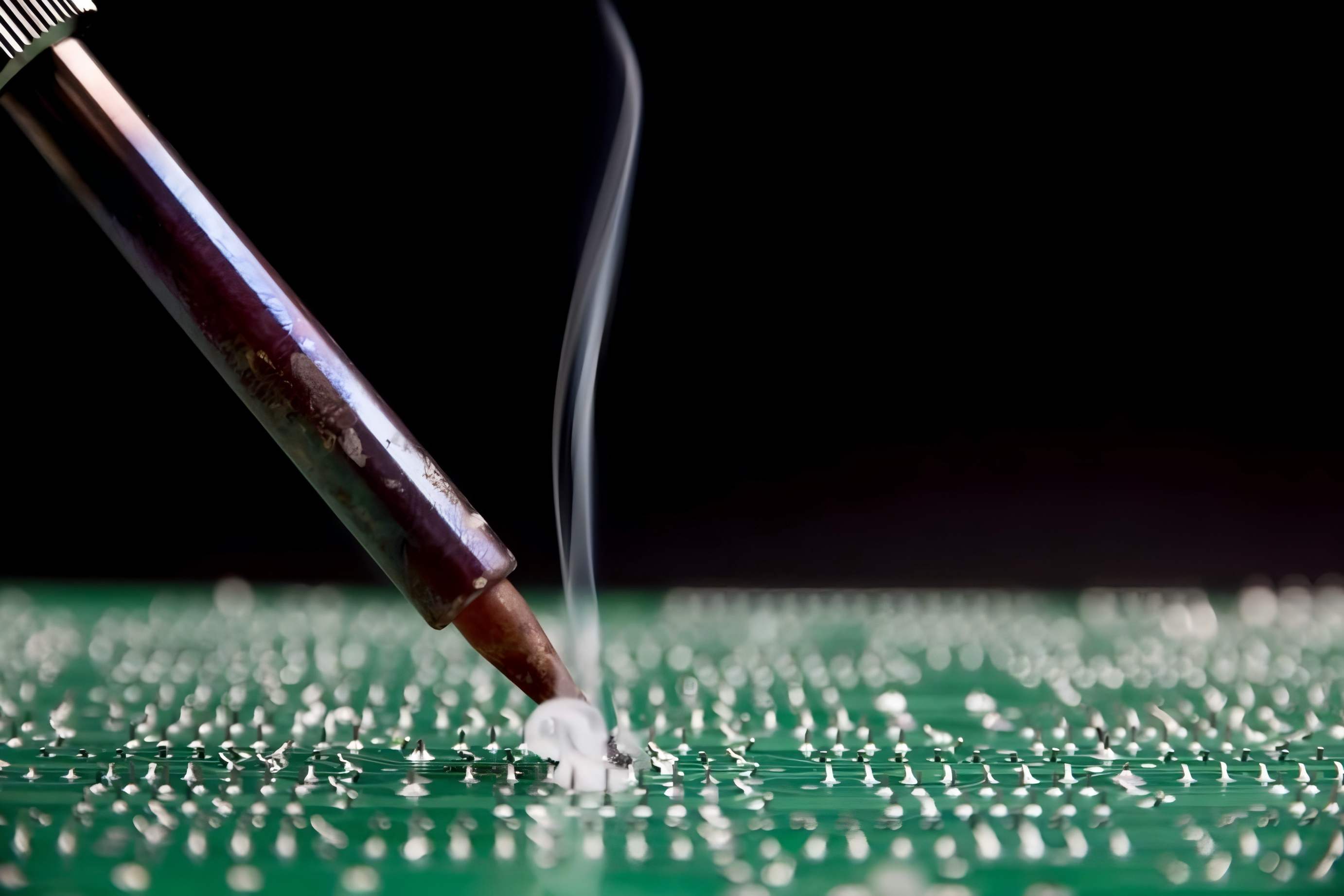

4、Fluxing Agent in Soldering

In the assembly of electronic devices, soldering plays a vital role in connecting components like transistors, capacitors, and resistors to printed circuit boards (PCBs). For soldering to be effective, metal surfaces must be clean and free of oxides or contaminants, which can prevent proper adhesion between the solder and the metals being joined. This is where KBF4 comes in as a fluxing agent.

As a flux, potassium tetrafluoroborate helps by cleaning metal surfaces during the soldering process. It reacts with and removes oxides, allowing the solder to flow smoothly and form strong, reliable joints between electronic components. The use of KBF4 as a fluxing agent is particularly beneficial in high-temperature soldering applications, as its stability ensures it remains effective even at elevated temperatures.

Moreover, KBF4’s action in fluxing helps prevent oxidation during the soldering process itself. This minimizes defects in solder joints, which is critical for the long-term performance of electronic devices. Poorly soldered connections can lead to issues such as intermittent electrical contact or complete device failure, so the role of KBF4 in ensuring high-quality solder joints is a distinct advantage.

5、Thermal Stability and Heat Management

One of the major challenges in modern electronics is the management of heat generated by high-performance components. Excess heat can degrade performance or even damage electronic devices, so managing thermal conductivity is critical in device design and manufacturing.

KBF4’s high thermal stability makes it valuable in processes that involve high temperatures, such as semiconductor fabrication or the development of heat-resistant materials. In particular, KBF4 is used in the production of boron nitride (BN), a compound known for its exceptional thermal conductivity and electrical insulation properties. Boron nitride is used as a thermal interface material, helping to dissipate heat from critical components like microprocessors and power transistors.

Boron nitride derived from KBF4 is an important material for advanced electronics, where heat management is crucial for maintaining performance and extending device lifespans. The ability of KBF4 to contribute to the production of such materials underlines its significance in high-temperature and high-performance applications.

6、Chemical Versatility and Customization

A significant principle behind the success of KBF4 in electronics is its chemical versatility. It can be combined with a range of other compounds to create custom solutions for specific manufacturing challenges. Whether it is being used in doping, etching, or fluxing, KBF4 can be modified to suit different manufacturing conditions.

For example, in doping, the concentration of boron released from KBF4 can be carefully controlled to ensure that semiconductor materials meet precise electrical specifications. Similarly, in etching and fluxing, KBF4’s reactivity can be adjusted depending on the types of materials being processed, allowing manufacturers to tailor its properties to specific needs.

This adaptability makes KBF4 an essential chemical in electronics, where precision and customization are often required to meet the demands of cutting-edge technologies.

7、Advantages of KBF4 in Electronics Manufacturing

The advantages of using potassium tetrafluoroborate in electronics manufacturing are numerous, including:

● Precision: KBF4 allows for controlled release of boron during semiconductor doping, ensuring uniformity and high-quality electronic components.

● Thermal Stability: Its resistance to high temperatures makes it ideal for processes like doping and etching, where elevated temperatures are necessary.

● Versatility: KBF4’s ability to act as a flux, dopant, and etching agent highlights its flexibility in various electronic manufacturing stages.

● Efficiency: In processes like fluxing, KBF4 enhances the quality of solder joints by removing oxides and preventing oxidation, improving the reliability of electronic assemblies.

● Cost-Effectiveness: Its widespread availability and effectiveness across multiple stages of electronic manufacturing make it a cost-efficient solution for manufacturers.

Potassium tetrafluoroborate (KBF4) plays a fundamental role in the electronics industry due to its unique chemical properties and versatility. Its ability to serve as a dopant, etching agent, and flux, along with its thermal stability, allows it to contribute significantly to the manufacturing of high-performance electronic devices. The compound’s precision, adaptability, and cost-effectiveness make it an invaluable asset in the development of modern electronics, ensuring both high-quality production and enhanced device performance.